Screw Dewatering is an essential process in various industries. It is primarily used for managing waste and reducing water content in sludge. The method has gained popularity due to its efficiency and energy-saving features.

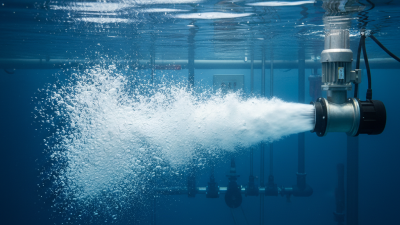

During Screw Dewatering, a screw conveyor moves material through a cylindrical screen. As the material progresses, water is removed, resulting in a drier product. This process is effective in wastewater treatment, agriculture, and mining. Users often report improved disposal costs and easier handling of solids.

However, while Screw Dewatering is beneficial, it is not without challenges. Maintenance can be demanding, and wear on the equipment is common. Operators need to monitor conditions closely to achieve optimal results. Overall, understanding the process and its potential pitfalls is crucial for successful implementation.

Screw dewatering plays a crucial role in wastewater treatment. This process uses a helical screw to extract water from sludge efficiently. According to recent industry reports, screw dewatering systems can achieve dryness levels of up to 30% to 50%, significantly reducing the volume of waste for disposal.

In many treatment plants, the use of screw dewatering has increased. Its efficiency is essential for resource optimization. This technology minimizes energy consumption compared to traditional methods. Moreover, the reduction in waste volume can lower disposal costs. However, proper maintenance of the systems is vital. Neglect can lead to breakdowns, resulting in increased downtime and costs.

Tips: Regularly inspect the screw and bearings. Timely maintenance can prevent costly repairs. Monitor the moisture content to optimize performance. Adjusting the configuration can lead to better results. Utilizing data-driven metrics can enhance efficiency further. It's essential to strike a balance between cost and effectiveness in operations.

| Parameter | Description | Importance |

|---|---|---|

| Process | A mechanical process that uses a screw conveyor to separate solid waste from liquids. | Helps in reducing the volume of sludge for easier handling and disposal. |

| Efficiency | Typically achieves up to 90% water removal from the solids. | Increases overall efficiency in wastewater treatment processes. |

| Applications | Used in municipal wastewater treatment, food processing, and various industrial sectors. | Provides flexibility to treat different types of waste efficiently. |

| Maintenance | Requires regular maintenance to ensure optimal performance. | Ensures longevity and reduces potential downtimes in operations. |

| Environmental Impact | Minimizes landfilling of waste through effective dewatering. | Promotes sustainable waste management practices. |

Screw dewatering is an effective method for removing water from solids. The mechanism relies on a screw conveyor, which moves material along a cylindrical chamber. As solids enter, the screw action compresses them, increasing pressure and squeezing out water. This process can efficiently reduce the moisture content of a wide range of materials.

Understanding the principles of this method is crucial. The design allows for continuous operation, which is beneficial in many applications. The average operating speed is crucial; too fast can lead to inefficient dewatering. Meanwhile, too slow may cause material build-up and affect performance. Maintaining the right balance is vital for optimal results.

Sometimes the system can face challenges. For instance, certain materials may not dewater effectively due to their properties. Operators might need to adjust parameters frequently. The process can also be sensitive to changes in feed rate and moisture levels. Regular monitoring ensures that the system runs smoothly, while also providing insights for continuous improvement.

This bar chart represents the dewatering efficiency of different types of sludge when using screw dewatering techniques. Efficient dewatering is crucial for effective waste management and water treatment processes.

Screw dewatering is an efficient method used to separate solids from liquids. At the heart of this system are key components that ensure proper functionality. A main part is the screw conveyor, which moves materials through an enclosed chamber. The design allows for consistent movement and controlled pressure. The pitch of the screw affects the rate of flow, making it crucial for efficiency.

Another vital component is the screen. This element filters out liquid as the material progresses. The size of the openings in the screen determines what solids remain. Regular maintenance on the screen is often overlooked. Clogging can occur, which reduces performance. Operators must be vigilant about this aspect.

Finally, the drive mechanism powers the system's operation. It converts electrical energy into mechanical motion. However, there can be challenges related to wear and tear over time. Users sometimes neglect to inspect these components regularly. Scheduled checks are essential for long-term reliability. Effective screw dewatering relies heavily on these interconnected elements working well together.

Screw dewatering is an essential process in various industries. It focuses on separating solids from liquids efficiently. The performance of screw dewaterers is measured using various metrics. Key factors include throughput, moisture content, and energy consumption. These metrics help determine the effectiveness of the system.

Throughput indicates how much material can be processed in a specific timeframe. It's crucial for optimizing operational efficiency. A high throughput often reflects a well-designed system. However, achieving high throughput doesn't always mean minimal moisture content. Sometimes, a trade-off occurs, leading to less ideal outcomes.

Industry standards play a vital role in assessing performance data. They provide benchmarks for moisture percentages and energy usage. Many facilities may find it challenging to meet these standards consistently. Continuous improvement and monitoring are necessary. Some operators might struggle with balancing efficiency and effectiveness. This can lead to operational inefficiencies that need reflection and strategizing.

Screw dewatering is gaining traction in various industries. It efficiently reduces the water content in sludges and slurries. This method employs a screw mechanism to extract water, making it effective for many applications.

In the food processing industry, screw dewatering is used to handle waste efficiently. It can significantly reduce the volume of waste produced. However, the process may need regular maintenance to ensure optimal performance. Similarly, in the wastewater treatment sector, it helps in treating biosolids. This has environmental benefits but can also generate operational challenges.

The agricultural sector benefits from this technology, especially in managing manure. By reducing moisture content, the transport of this material becomes easier. However, careful monitoring is required to avoid nutrient loss. In construction, screw dewatering aids in managing excavation waste, but it can be complicated. Each industry sees value in screw dewatering, yet effectiveness can fluctuate based on specific conditions.