In the world of industrial mixing, selecting the right equipment can significantly impact production efficiency and product quality. As we venture into 2025, the importance of finding the best tank paddle mixer becomes even more pronounced. Renowned expert Dr. Emily Hart, a leading figure in the mixing technology industry, emphasizes this point by stating, "The right tank paddle mixer can transform your process, enhancing both performance and reliability." This sentiment echoes the sentiments of many professionals who understand that not all mixers are created equal, and a well-chosen mixer can lead to superior outcomes in various applications.

With advancements in technology and evolving industry standards, the criteria for choosing a tank paddle mixer are changing. Factors such as mixing speed, energy efficiency, and maintenance needs are now at the forefront of decision-making processes. Additionally, as industries strive for sustainability and cost-effectiveness, selecting an ideal mixer becomes pivotal in achieving operational goals.

This guide will explore the essential considerations for selecting the perfect tank paddle mixer in 2025, providing insights into the features, specifications, and technologies that matter most. Whether you're involved in food processing, chemical manufacturing, or wastewater treatment, understanding the nuances of tank paddle mixers will ensure that your equipment aligns with your production needs and contributes to your success.

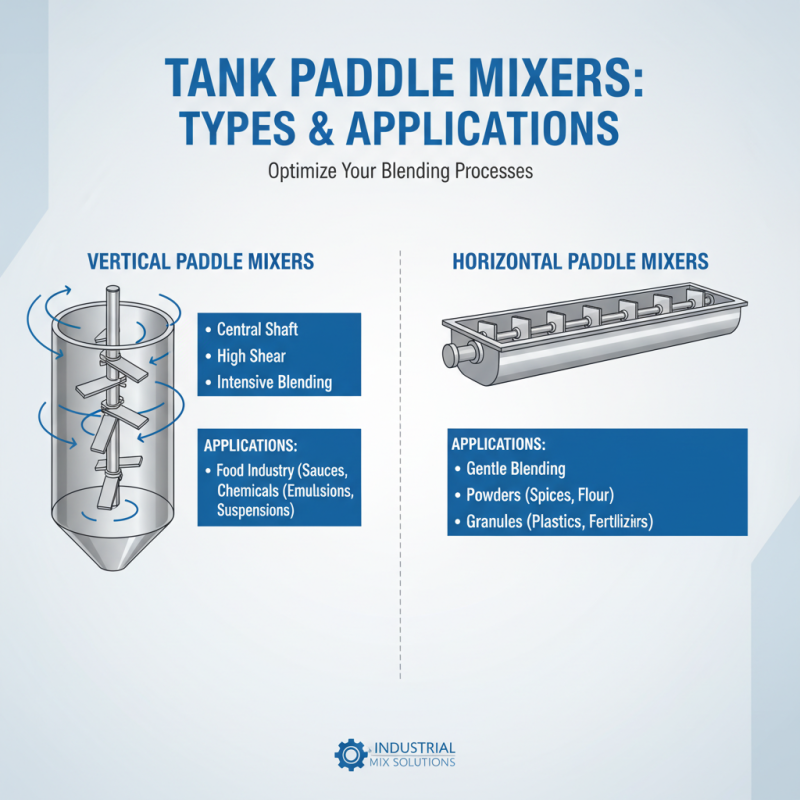

Tank paddle mixers are essential equipment in various industrial processes, playing a crucial role in ensuring uniform blending of materials. Understanding the different types of paddle mixers available can help operators make informed choices to optimize their mixing applications. There are mainly two types: vertical paddle mixers and horizontal paddle mixers. Vertical mixers often feature a central shaft with paddles arranged around it, making them ideal for applications that require intensive mixing and high shear rates, such as in the food and chemical industries. In contrast, horizontal paddle mixers are better suited for bulk materials and lighter mixing tasks, utilizing a series of paddles positioned along a horizontal axis to provide gentle blending without excessive aeration.

The applications of tank paddle mixers are diverse, spanning industries like pharmaceuticals, wastewater treatment, and logistics for food products. In the pharmaceutical sector, high efficiency and precise mixing are vital; paddle mixers help achieve consistency in active ingredient distribution. Wastewater treatment facilities utilize these mixers to ensure even treatment of sludge and chemicals, enhancing purification processes. Moreover, in food production, tank paddle mixers enable the thorough mixing of ingredients, ensuring quality and safety standards are met without compromising the texture or flavor of the final product. Understanding these aspects not only aids in selecting the right mixer but also optimizes operational effectiveness across various industries.

When selecting the best tank paddle mixer, several key features significantly influence performance and efficiency. One crucial aspect to consider is the mixer’s blade design and configuration. According to the latest market analysis by DataBridge Market Research, innovations in blade geometry have shown to increase mixing efficiency by up to 30%. A well-designed paddle can enhance fluid dynamics, ensuring that materials are uniformly mixed, reducing the time spent in operations.

Another essential feature is motor power and adjustable speed settings, which impact the versatility of the mixer. The American Society of Mechanical Engineers (ASME) reports that mixers with variable speed motors can accommodate a wider range of viscosities and material types, making them more versatile in different industrial applications. With the rise in demand for customized mixing solutions across various sectors, a paddle mixer equipped with these capabilities can provide a significant competitive edge.

Furthermore, ease of maintenance and durability are factors that cannot be overlooked; mixing equipment that simplifies maintenance contributes not only to lower operational costs but also to improved longevity and reliability in demanding environments.

When selecting a tank paddle mixer in 2025, it's essential to consider the top brands and models that excel in performance and reliability. Leading manufacturers focus on engineering innovations that enhance mixing efficiency, ensuring that materials are blended uniformly in various tank sizes. These mixers often come with advanced features such as adjustable paddle angles and variable speed settings, allowing for customization based on the specific needs of different applications.

In recent years, models equipped with energy-efficient motors have gained popularity, reducing operational costs while maintaining high mixing standards. Additionally, many of the latest tank paddle mixers boast robust designs, ensuring durability in challenging environments. Buyers should prioritize models that offer ease of maintenance and environmentally friendly materials. By selecting from the best brands and their top-rated models, users can ensure optimal mixing performance and longevity in their operations for the year ahead.

When selecting a paddle mixer, performance metrics such as mixing efficiency, power consumption, and agitator design are crucial to ensuring optimal results. A recent industry report indicates that high-performance paddle mixers can achieve a mixing efficiency of up to 95%, significantly reducing mixing times compared to traditional methods. Power consumption is another vital consideration, with advanced models demonstrating energy savings of up to 30% without compromising on mixing quality. Understanding these metrics allows operators to make informed decisions that enhance productivity and reduce operational costs.

Tips: Always consider the specific characteristics of your materials, as viscosity and particle size can significantly impact mixer performance. It is also advisable to evaluate the mixer’s design and how it interacts with the tank shape to ensure uniformity in mixing. Regularly maintaining the equipment to align with performance benchmarks can prolong its lifespan and prevent costly downtimes.

Moreover, innovative sensor technologies are now being integrated into paddle mixers, providing real-time data on mixing conditions such as temperature and consistency. These advancements enable operators to fine-tune their processes, ensuring optimal performance and adherence to quality standards. Ultimately, investing in a paddle mixer that meets or exceeds industry performance metrics will facilitate improved operational efficiency and product quality in 2025 and beyond.

To ensure optimal functionality of your paddle mixer, regular maintenance is key. Start by routinely inspecting the mixer’s blades and paddles for wear and tear. Over time, these components can become less effective at mixing due to buildup or damage, so thorough cleaning after each use is essential. Use a non-corrosive cleaner to prevent any deterioration on the surfaces. Pay attention to the shaft and bearings as well; lubricate them according to the manufacturer's guidelines to minimize friction and extend their lifespan.

Another crucial aspect of maintenance is to check for any electrical or mechanical issues. Regularly examine wire connections and ensure that there is no fraying or wear. Additionally, monitor the mixer for any unusual noises or vibrations during operation, as these may indicate underlying problems. Implementing a routine schedule for checking these elements will not only enhance the efficiency of the paddle mixer but also reduce the chances of downtime. By adhering to these maintenance tips, users can optimize the performance and longevity of their paddle mixers.

| Feature | Description | Maintenance Tip |

|---|---|---|

| Motor Power | Typically ranges from 0.5 to 15 HP depending on the application. | Regularly check motor bearings and lubrication to ensure efficiency. |

| Blade Material | Common materials include stainless steel, carbon steel, and plastic composites. | Inspect blades for wear and corrosion; replace if necessary to maintain performance. |

| Mixer Speed | Variable speeds available, often adjustable via VFD for optimal mixing. | Monitor speed settings and adjust according to viscosity changes in the tank contents. |

| Tank Compatibility | Can be designed to fit various tank sizes and shapes. | Ensure proper fitting to avoid turbulence and maintain optimal mixing efficiency. |

| Installation Type | Can be fixed, portable, or mounted to different tank profiles. | Regularly check the mounting hardware for tightness and integrity. |

| Cost | Prices range significantly based on specifications, from hundreds to thousands. | Consider life-cycle costs — efficiency can outweigh initial investment. |