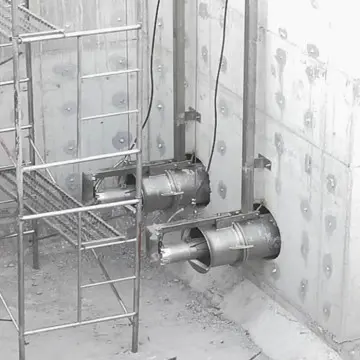

Carbon steel lined plastic frame blade mixer for flocculation tank

Structural Components

1.Mixing Frame: Made of a metal frame, its shape matches the container to ensure no dead corners during mixing.

2.Drive Unit: Includes a motor and a reducer, providing the power for mixing.

3.Shaft and Support: The mixing shaft connects the drive unit to the mixing frame, and the support structure ensures stable operation.

4.Container: Used to hold materials, typically made of stainless steel for corrosion resistance and easy cleaning.

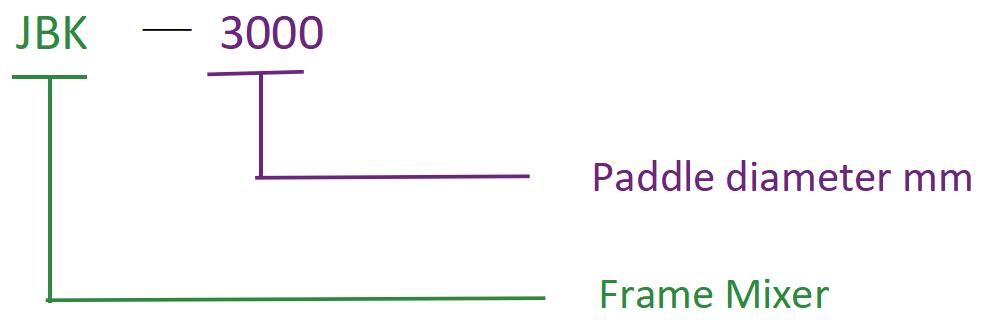

Model of Model Denotation

Main technical parameters and installation dimensions:

Model |

Pool size m |

Mixer size mm |

Motor power kw |

Rotation speed r/min |

|||||||

A×B |

H |

D |

h0 |

h1 |

Ⅰ |

Ⅱ |

Ⅲ |

Ⅰ |

Ⅱ |

Ⅲ |

|

JBK-1700 |

2.2×2.2 |

3.4 |

1700 |

2600 |

400 |

0.75 |

0.37 |

0.37 |

8 |

5.2 |

3.9 |

JBK-2875 |

3.25×3.25 |

4 |

2850 |

3500 |

350 |

5.2 |

3.9 |

3.2 |

|||

JBK-3000 |

3.5×3.5 |

3.55 |

3000 |

2200 |

550 |

0.37 |

0.25 |

0.18 |

3.9 |

2.5 |

1.8 |

JBK-3850 |

4.3×4.3 |

4 |

3850 |

1200 |

1.1 |

0.75 |

0.55 |

1.5 |

|||

4.7×4.7 |

3.4 |

1400 |

3.2 |

2.5 |

|||||||

Working Principle

The motor drives the mixing shaft to rotate through the reducer, causing the mixing frame to move accordingly. This pushes the materials to circulate within the container, achieving mixing and homogenization.

Main Features

1. Suitable for High-Viscosity Materials: Ideal for mixing high-viscosity materials or those containing solid particles.

2. Uniform Mixing: The design of the mixing frame ensures thorough mixing with no dead corners.

3. Easy Operation: Simple structure, easy to operate and maintain.

4. High Durability: Made of corrosion-resistant materials like stainless steel, ensuring a long service life.

Application Fields

1. Chemical Industry: Used for mixing high-viscosity chemicals, resins, adhesives, etc.

2. Food Industry: Used for stirring high-viscosity foods such as chocolate, jam, etc.

3. Pharmaceutical Industry: Used for mixing ointments, emulsions, etc.

4. Other Industries: Such as coatings, inks, cosmetics, etc.

Selection and Maintenance

1. Selection: Choose the appropriate model based on material viscosity, container size, and production requirements.

2. Maintenance: Regularly inspect the mixing shaft, frame, and drive unit, and replace worn parts promptly. Keep the equipment clean.

Safety precautions

1. Pre-Operation Check: Ensure the equipment is free of abnormalities before operation.

2. Protective Measures: Avoid contact with rotating parts during operation.

3. Emergency Shutdown: Immediately stop and inspect the equipment in case of abnormalities.

The frame mixer has a simple structure and is easy to operate, making it suitable for mixing high-viscosity materials. It is widely used in industries such as chemicals, food, and pharmaceuticals. Proper selection and maintenance can ensure its efficient operation.