Deepwater self-priming submersible jet aerator for river management

Working principle

The jet aerator is mainly based on the Venturi principle. When it is in operation, the impeller of the submersible pump rotates at a high speed, causing the liquid to be ejected from the nozzle at a high speed. When the high-speed flowing liquid passes through the gas mixing chamber, a vacuum is formed, and a large amount of air is sucked in through the air intake pipe. After the air enters the gas mixing chamber, it mixes violently with the liquid at the throat of the Venturi tube and is cut into fine bubbles to form a gas-liquid mixture. Then, the mixture is discharged through the diffuser tube. The air rises in the water as fine bubbles, dissolving oxygen into the water.

Model Denotation

parameters and selection

|

Model |

QSB0.75 |

QSB1.5 |

QSB2.2 |

QSB3 |

QSB4 |

QSB5.5 |

QSB7.5 |

|

Motor power kw |

0.75 |

1.5 |

2.2 |

3 |

4 |

5.5 |

7.5 |

|

electric current A |

2.9 |

3.7 |

5 |

6.4 |

8.2 |

12.4 |

16.3 |

|

Voltage V |

380 |

||||||

|

Speed r/min |

2900 |

2900 |

2900 |

2900 |

2900 |

1470 |

1450 |

|

Frequency HZ |

50 |

||||||

|

Insulation class |

F级 |

||||||

|

Maximum diving depth m |

1.5 |

2 |

3.5 |

4 |

4.5 |

5 |

5.5 |

|

Intake air volume m³/h |

10 |

22 |

35 |

50 |

75 |

85 |

100 |

|

Intake pipe mouth mm |

32 |

32 |

50 |

50 |

50 |

50 |

50 |

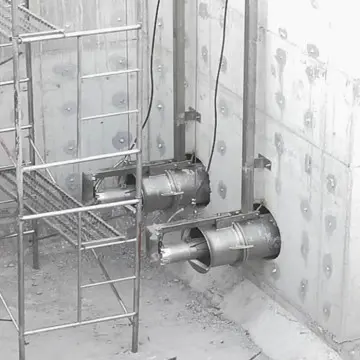

Structural composition

It is mainly composed of a submersible motor pump, a Venturi tube, a diffuser tube, an air intake pipe, and a silencer, etc. Among them, the submersible motor pump provides the power to make the liquid flow at a high speed; the Venturi tube includes a nozzle, an air suction chamber, and a throat, which are used to generate a negative pressure to suck in air and mix it; the diffuser tube discharges the gas-liquid mixture, reducing the speed and increasing the pressure.

Characteristics

1. High Efficiency and Energy Saving: As the water depth increases, the oxygenation efficiency improves. The oxygenation efficiency of the new type of jet aerator can reach 35% at a water depth of 8 meters, and the air-water ratio is only 4:1, with relatively low energy consumption.

2. Less Prone to Blockage: It adopts a large-caliber hydraulic spray head and has a simple structure. During normal operation, it is almost free from blockage, and it is easy to disassemble and assemble, as well as to inspect or replace components.

3. Strong Applicability: The oxygenation and mixing can be controlled separately. The air volume and circulating water can be adjusted according to requirements. When the air supply is stopped, it can still maintain the mixing state, making it suitable for biochemical treatment systems with alternating anaerobic/aerobic cycles.

4. Convenient Installation: It can be installed at a position above the water surface that is convenient for operation, allowing the operation status to be observed at any time. Faults can be found and eliminated in a timely manner. It can also be installed with water while the sewage treatment system is in normal operation.

5. Long Service Life: It mostly uses materials such as stainless steel. Compared with traditional micro-porous aerators, it has a longer service life.

6. Low Noise: Unlike general aerators and blowers, it does not produce much noise, which can reduce the noise pollution of the sewage biochemical treatment system.

Application

1. Sewage Treatment: It is widely used in the sewage treatment of industries such as leather, pulp and paper making, and chemicals. It is used for aeration and agitation in aerated grit chambers, pre-aeration tanks, oxidation tanks, etc., and can also be used for the aerobic digestion of sludge. By controlling the air supply volume, denitrification and nitrification can be achieved.

2. Aquaculture: It is used to increase the oxygen content in aquaculture ponds, improve the aquaculture environment, and promote the growth of aquatic animals.

3. Landscape Water Maintenance: It is applied to landscape water bodies to maintain the water quality, prevent eutrophication of the water body, and create a good landscape effect.

4. Tap Water Treatment: It is used in the iron and manganese removal process in the front section of the tap water process, as well as in the water replenishment and circulation process of tap water in high-rise buildings, etc.