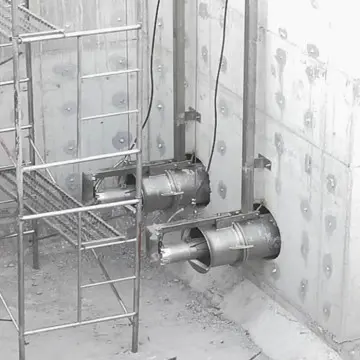

Floating cylinder micro-nano bubble generator for sewage treatment

Definition and Principle

1. Definition: A micro-nano bubble generator is a device capable of producing tiny bubbles with diameters in the micrometer and nanometer range.

2. Principle: There are mainly multiple methods. For example, through a high-pressure dissolved air system, air or other gases are dissolved in water under high pressure, and then the micro-nano bubbles are formed by decompression and release. Or technologies such as ultrasonic waves and jets are used to break the gas into tiny bubbles. At the same time, the bubbles' surfaces are charged, enhancing their stability and physical and chemical properties.

Model Denotation

parameters and selection

|

Model |

Power supply V/HZ |

Motor power kw |

Speed r/min |

Oxygenation capacity kgO2/h |

Circulation flux m³/h |

|

LJMNG750 |

220V/380V/50HZ |

0.75 |

2850 |

2.0-3.0 |

120 |

|

LJMNG1200 |

220V/380V/50HZ |

1.2 |

2850 |

2.4-3.2 |

150 |

|

LJMNG1500 |

220V/380V/50HZ |

1.5 |

2850 |

3.2-4.0 |

200 |

|

LJMNG2200 |

380V/50HZ |

2.2 |

2850 |

4.0-5.0 |

250 |

|

LJMNG3000 |

380V/50HZ |

3 |

2850 |

6.5-7.2 |

390 |

|

LJMNG4000 |

380V/50HZ |

4 |

2850 |

7.5-9.0 |

440 |

|

LJMNG5500 |

380V/50HZ |

5.5 |

2850 |

9.3-12 |

650 |

|

LJMNG7500 |

380V/50HZ |

7.5 |

2850 |

12-18 |

930 |

|

LJMNG9000 |

380V/50HZ |

9 |

2850 |

18-24 |

1230 |

Structural composition

1. Gas Intake System: Responsible for introducing gas into the generator. It usually includes a gas compressor, a gas flow meter, etc., to precisely control the gas intake.

2. Mixing System: Enables the gas and water to be fully mixed. Common devices include venturi tubes, agitators, etc., to promote the dispersion of gas in water.

3. Generation System: It is the core part for generating micro-nano bubbles. According to different principles, there are various designs, such as high-pressure dissolved air tanks, ultrasonic transducers, jet nozzles, etc.

4. Control System: Used to monitor and adjust the operating parameters of the generator, such as pressure, flow rate, and bubble particle size, to ensure stable bubble generation.

Characteristics

1. Small Bubble Particle Size: The bubble diameter is usually between 1 micrometer and 1000 nanometers. Compared with ordinary bubbles, it has a larger specific surface area, which can significantly improve the gas-liquid mass transfer efficiency.

2. Surface Charge Characteristics: The surfaces of micro-nano bubbles are charged, giving them good stability. They are not easy to coalesce and can exist in water for a long time.

3. Efficient Mass Transfer: Due to the large specific surface area, in fields such as water treatment and aquaculture, oxygen, ozone, etc. in the gas can be quickly transferred into the liquid, improving the reaction efficiency.

Advantages

1. Enhanced Treatment Effect: In sewage treatment, it can strengthen the degradation and removal of pollutants. In aquaculture, it can increase the dissolved oxygen content in the water body and improve the breeding environment.

2. Energy Saving and Consumption Reduction: Compared with traditional aeration equipment, it has high mass transfer efficiency and can reduce energy consumption.

3. Wide Application Range: It can be used in many fields such as water treatment, agricultural irrigation, food processing, and healthcare.

Application

1. Water Treatment: Used for aeration, phosphorus and nitrogen removal in sewage treatment, as well as disinfection, iron and manganese removal in drinking water, etc.

2. Aquaculture: Increases the dissolved oxygen in water, promotes the growth of aquatic animals, and reduces the occurrence of diseases.

3. Agriculture: Applied to the oxygenation of irrigation water, improving the respiration of crop roots and promoting growth.

4. Food Processing: Used for the carbonation of beverages, food preservation, etc.

Maintenance and Upkeep

1. Regularly check the connection of each component to ensure there is no looseness or leakage.

2. Clean the filters of the gas intake system and the mixing system to prevent impurities from clogging.

3. Replace vulnerable parts such as nozzles and seals regularly according to the requirements of the equipment instruction manual.

4. Calibrate and maintain the control system to ensure its accuracy and reliability.