High concentration and low salt wastewater pool glass fiber reinforced plastic hyperbolic mixer

Working Principle

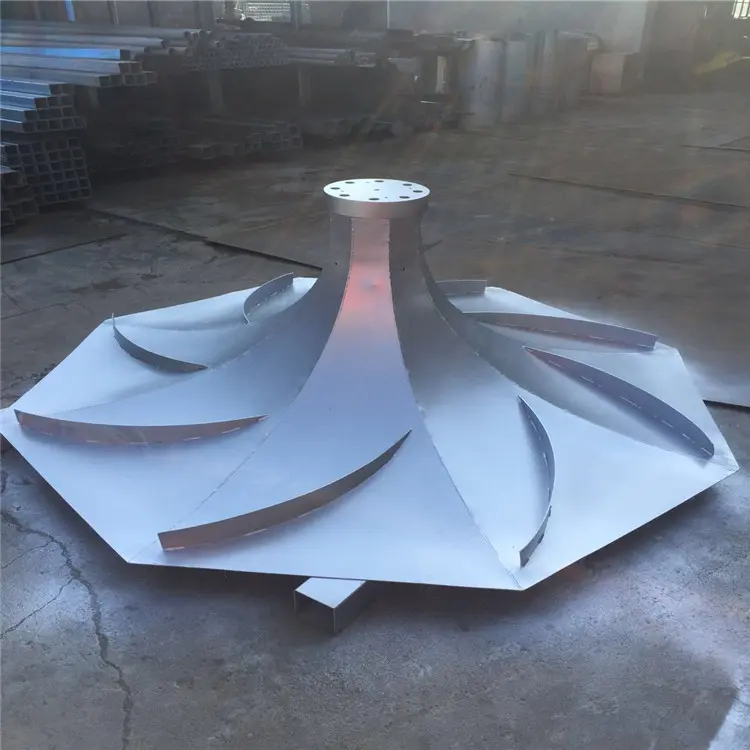

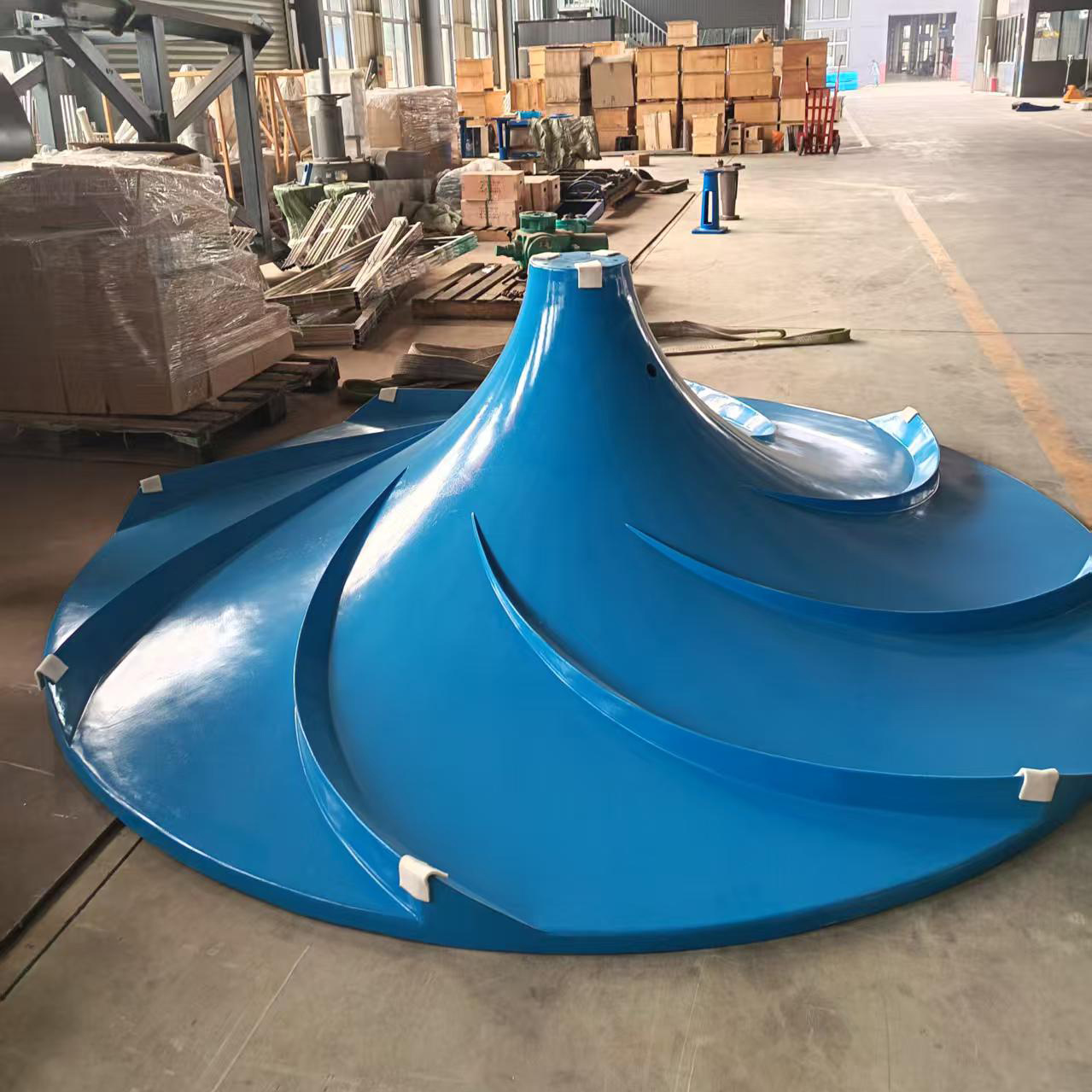

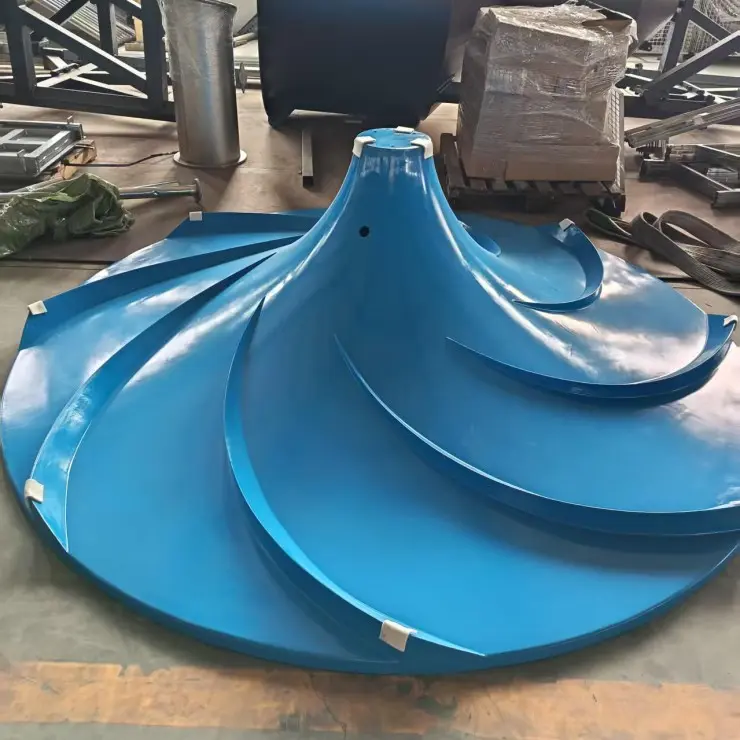

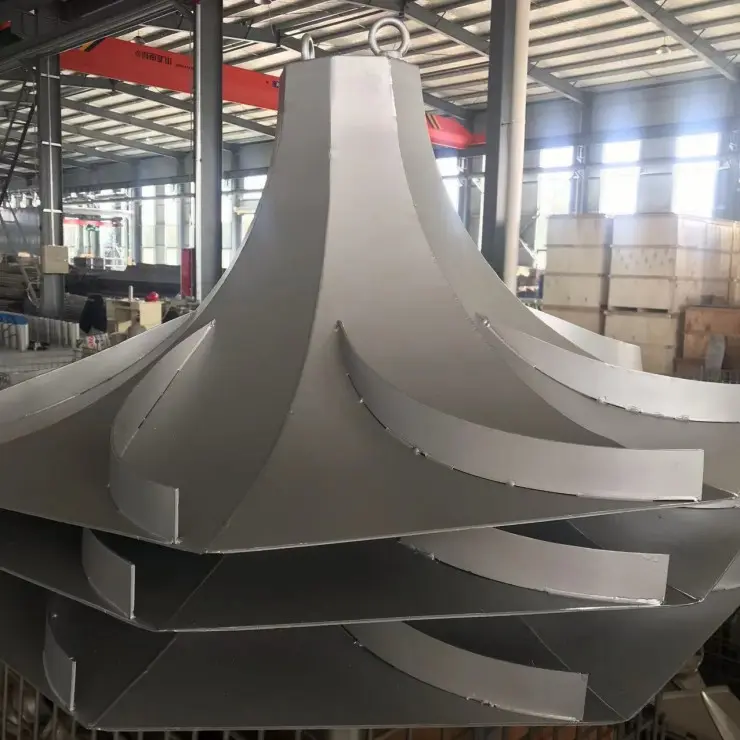

1. Hyperboloid Impeller: The impeller features a unique design with hyperboloid surfaces on both the upper and lower sides, generating intense radial and axial flows during rotation.

2. Fluid Movement: The rotation of the impeller drives the liquid to form an up-and-down circulating flow, achieving efficient mixing.

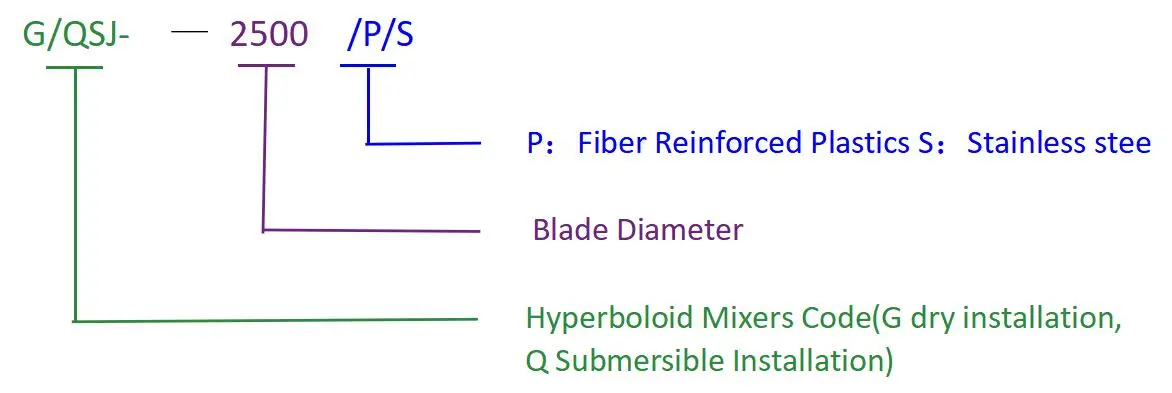

Model of Model Denotation

Technical Parameters

Model |

Impeller diameter (mm) |

Rated speed(r/min) |

Rated power(kw) |

Service scope(Pool width m) |

Machine weight(kg) |

|

Impeller stainless steel |

Impeller fiberglass |

|||||

G/QSJ500 |

500 |

40--250 |

0.75--1.5 |

1--3 |

320 |

300 |

G/QSJ1000 |

1000 |

30--80 |

1.1--2.2 |

2--5 |

700 |

500 |

G/QSJ1500 |

1500 |

30--60 |

1.5--3 |

3--6 |

850 |

600 |

G/QSJ2000 |

2000 |

20--42 |

2.2--4 |

6--14 |

1100 |

650 |

G/QSJ2500 |

2500 |

20--40 |

3--5.5 |

10--18 |

1200 |

700 |

G/QSJ3000 |

3000 |

20--30 |

4--7.5 |

12--22 |

1250 |

900 |

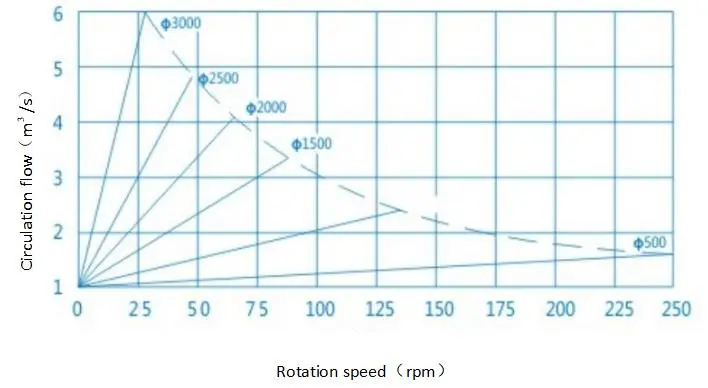

Rotary and Circulating flow Curve

Main Components

1. Impeller: The core component, designed with a hyperboloid shape, determines the mixing efficiency.

2. Motor: Drives the impeller rotation, typically installed vertically.

3. Gear Reducer: Reduces motor speed and increases torque.

4. Support Frame: Supports the motor and gear reducer, ensuring stable operation.

5. Sealing Device: Prevents liquid leakage, ensuring equipment safety.

Features

1. Efficient Mixing: The hyperboloid impeller creates strong fluid movement, ensuring excellent mixing performance.

2. Low Energy Consumption: Optimized design minimizes energy loss, reducing operating costs.

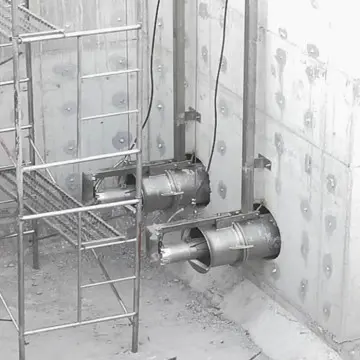

3. Compact Structure: Vertical design saves space and facilitates installation.

4. Stable Operation: Low vibration and noise, easy maintenance.

5. Strong Adaptability: Suitable for various liquid media with good corrosion resistance.

Application Fields

1. Wastewater Treatment: Used for mixing and stirring in aeration tanks, anaerobic tanks, sludge tanks, etc.

2. Chemical Industry: Used for liquid mixing in reactors and mixing tanks.

3. Food Industry: Used for material mixing in mixing tanks and fermentation tanks.

4. Pharmaceutical Industry: Used for liquid mixing and mass transfer in drug production.

5. Environmental Engineering: Used in environmental projects such as wastewater treatment and sludge treatment.

Selection and Maintenance

1. Selection Guidelines: Choose the appropriate model based on processing capacity, liquid properties, and mixing requirements.

2. Maintenance Recommendations: Regularly inspect the impeller, sealing device, and motor, and clean debris promptly to ensure normal operation.

Common Issues

1. Poor Mixing Performance: May be caused by impeller wear or insufficient speed; inspect the impeller and motor.

2. Excessive Noise: May result from bearing damage or unstable installation; check the bearings and support frame.

3. Liquid Leakage: Caused by sealing device failure; replace the sealing device promptly.

The hyperboloid mixer is widely used in wastewater treatment, chemical, food, and pharmaceutical industries due to its efficient mixing, low energy consumption, and compact structure. Proper selection and regular maintenance are key to ensuring its long-term stable operation.