Delivered a rotary screen cleaner to help customers complete projects

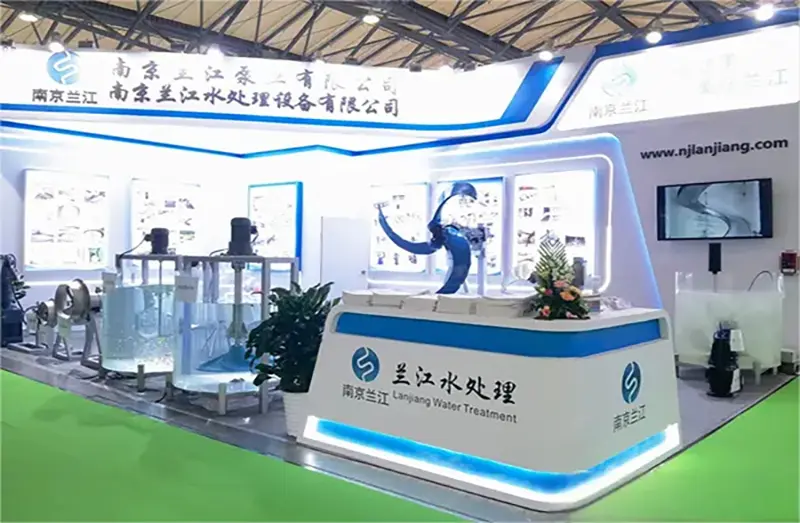

Recently, Nanjing Lanjiang Pump Industry Co., Ltd., relying on its outstanding production scheduling capabilities and technical strength, successfully delivered a batch of rotary screen decontamination machines for the sewage treatment project that Mr. Hu was responsible for within the urgent delivery period, helping the project to be completed with high quality within the limited date. This cooperation not only reflects the company's "customer first" service concept, but also highlights its professional advantages in the field of environmental protection equipment manufacturing.

Lanjiang Pump Industry faces the challenge of urgent orders

Due to the adjustment of the construction period, a municipal sewage treatment project undertaken by Mr. Hu needs to complete the purchase and installation of the rotary screen decontamination machine within 30 days, while the regular production cycle of this equipment is 45 days. Faced with urgent needs, Nanjing Lanjiang Pump Industry quickly set up a special team, and through optimizing the design process, activating the backup supply chain, and 24-hour shift production, it compressed the delivery cycle to 28 days, and won critical buffer time for the project.

Rotary screen cleaner: the "first line of defense" for sewage treatment

As the core pretreatment equipment of the sewage treatment system, the rotary screen cleaner is mainly used to intercept and remove suspended matter and solid waste (such as plastics, branches, etc.) in the water flow to prevent subsequent equipment from clogging. Its working principle is to continuously salvage the intercepted debris from the water to the conveyor through the circulating rake chain to achieve automatic sewage cleaning. This type of equipment produced by Nanjing Lanjiang uses high-strength stainless steel material and modular design. It has the advantages of strong corrosion resistance, low operating noise, and interception efficiency of more than 95%. It is widely used in municipal pipe networks, industrial wastewater and river management.

Technical customization + full-process service to ensure seamless connection of the project

The equipment parameters must be perfectly matched with the on-site working conditions, otherwise it will affect the overall project progress. Mr. Hu emphasized. Based on the average daily processing volume of the project (20,000 tons), water quality characteristics and other data, the Nanjing Lanjiang technical team customized a model with a screen gap of 10mm, and upgraded the drive system to adapt to high-load operation. During the production process, the company monitored the progress in real time through the digital management system and completed the equipment assembly 3 days ahead of schedule; after delivery, the engineer stayed on site for 48 hours to guide the installation and commissioning to ensure the successful start-up of the equipment. After testing, the batch of equipment operated stably, and the average daily sewage removal exceeded the design standard by 15%, which was highly recognized by the project party.

Practice the original intention with craftsmanship and empower green infrastructure

Nanjing Lanjiang Pump Industry has been deeply involved in the environmental protection equipment industry for more than 20 years. Its rotary screen sewage remover series has served more than a thousand sewage treatment projects across the country. The person in charge of the company said: "Short-term delivery does not mean compromising quality. We have achieved dual guarantees of efficiency and quality through standardized module inventory and flexible production lines."