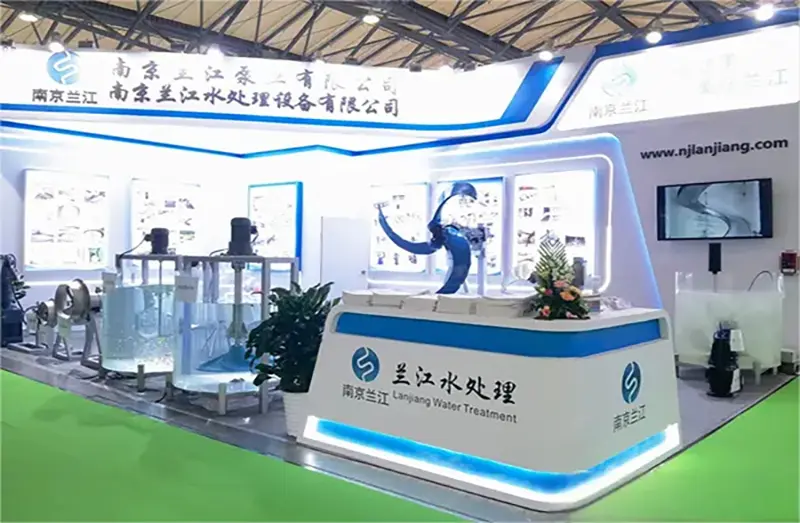

The "golden partners" of wastewater treatment plant are undoubtedly Nanjing Lanjiang Water Treatment Equipment Co., Ltd's four pollution reduction "weapons"!

Not long ago, the General Office of the State Council issued the "Opinions on Promoting Urbanization Construction with County Towns as an Important Carrier", which once again proposed "differentiated and precise improvement of sewage treatment standards", requiring the expansion and renovation of existing sewage treatment plants and odor control, and gradually reducing the scale of sludge landfill.

As early as February this year, the "Guiding Opinions on Accelerating the Construction of Urban Environmental Infrastructure" has included "wastewater treatment and resource utilization" in the category of urban infrastructure, and set specific goals such as adding 20 million cubic meters of sewage treatment capacity per day, a county sewage treatment rate of more than 95%, and a harmless disposal rate of urban sludge of 90%.

Now, the pressure of actual operation is on the sewage treatment plant. As the main carrier of sewage treatment activities, the sewage treatment plant must not only effectively expand its capacity to improve its sewage absorption and disposal capacity, but also take into account the product end, that is, the resource treatment of sludge. If you want to break through, you naturally need auxiliary "tools" to improve production efficiency. The four equipments promoted by Nanjing Lanjiang Pump Industry Co., Ltd. are all "experts in this field".

4 Sludge Scrapers: Smooth and efficient collection and transmission make sludge recovery and disposal easier

1. ZBGN peripheral transmission bridge type scraper

Integrating a more optimized drive device, a more practical logarithmic spiral scraper, and a more load-bearing hinged structure, this equipment is widely used in sewage treatment sedimentation tanks, and can skim the sludge and scum deposited at the bottom to the slag collection bucket for the next step of processing. At the same time, to ensure safety, this equipment also adds an automatic rake setting, which can avoid obstacles in time to avoid damage to the machine.

2. ZCGN type center transmission vertical frame scraper

Different from the bridge-type scraper, the center-drive vertical frame type uses the scraper arm fixed on the rotating vertical frame to drive the floating slag and deposited sludge on the liquid surface to concentrate in a gradually shrinking area, and scrape it into the slag collecting bucket and discharge it out of the circular settling tank. Through this principle, this equipment can effectively reduce the workload of the sewage treatment tank. With a simpler and lighter structure, it can save operating costs and facilitate maintenance and management while ensuring efficient operation.

3. WNG thickening tank hanging center drive scraper

This equipment is suitable for gravity sludge thickening tanks in sewage treatment plants. It uses a vertical reducer with an electric motor and a slewing bearing with external teeth to drive the scraper arm to rotate around the central axis of the tank, pushing the sludge deposited on the bottom of the tank from the outside to the mud collection pit in the center of the tank. Similarly, to ensure safe operation, this equipment is also equipped with an over-torque protection mechanism. When the scraper encounters problems such as foreign matter jamming or excessive mud accumulation, the power supply is cut off in time and an alarm is sounded.

4. TGN type travelling type lifting rake scraper

In another scene of the sewage treatment plant - the horizontal flow sedimentation tank, the mobile type lifting rake mud scraper will have a better working performance. This equipment can adapt to two scenarios: the mud collecting tank/slag collecting tank is set at one end or at two ends. The mud scraper rake is used to continuously descend and lift to scrape and transport the sludge and slag to the end point. What is even more "amazing" is that this equipment can realize random control and remote control, greatly reducing manpower requirements and effectively improving productivity.