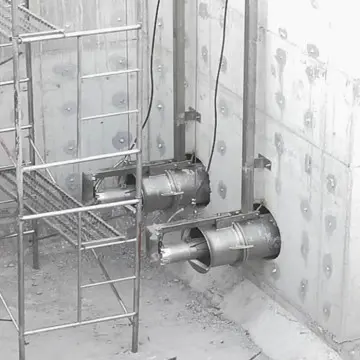

Non-clogging through-the-wall reflux pump for wastewater treatment

Structure

1. Pump Body: Includes the pump casing and impeller, responsible for transporting sludge.

2. Motor: Provides power to drive the pump.

3. Sealing Device: Prevents sludge leakage and ensures normal operation of the equipment.

4. Control System: Used to adjust the pump's flow rate and operating status.

5. Mounting Bracket: Secures the pump body, ensuring stable operation.

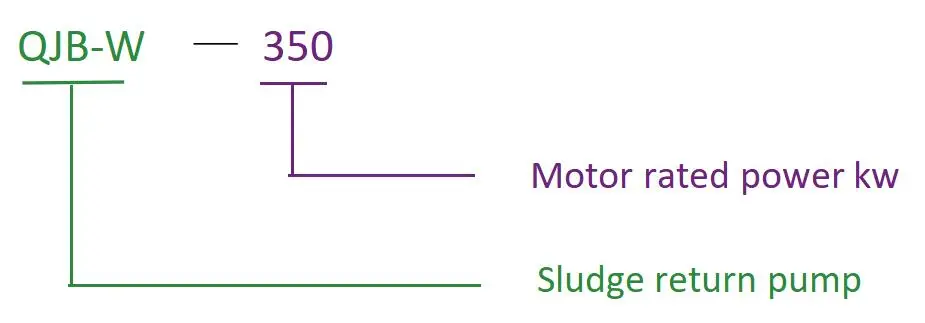

Model of Model Denotation

Model |

Motor power (kw) |

Rated current (A) |

Impeller diameter (mm) |

Protection grade |

Insulation class |

Nominal diameter (mm) |

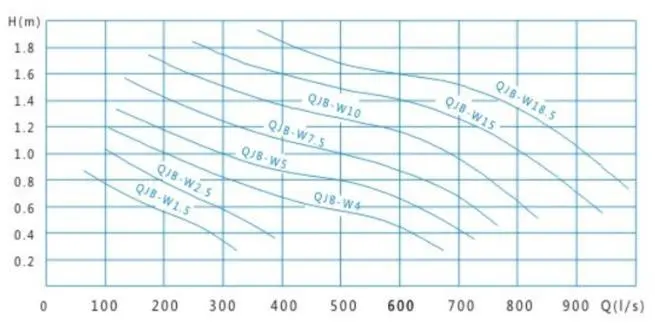

QJB-W1.5 |

1.5 |

4.1 |

400 |

IP68 |

F |

400 |

QJB-W2.5 |

2.5 |

6.8 |

400 |

IP68 |

F |

400 |

QJB-W4 |

4 |

15 |

615 |

IP68 |

F |

600 |

QJB-W5 |

5 |

16 |

615 |

IP68 |

F |

600 |

QJB-W7.5 |

7.5 |

23 |

615 |

IP68 |

F |

600 |

QJB-W10 |

10 |

30 |

615 |

IP68 |

F |

600 |

QJB-W15 |

15 |

42 |

615 |

IP68 |

F |

600 |

QJB-W18.5 |

18.5 |

52 |

615 |

IP68 |

F |

600 |

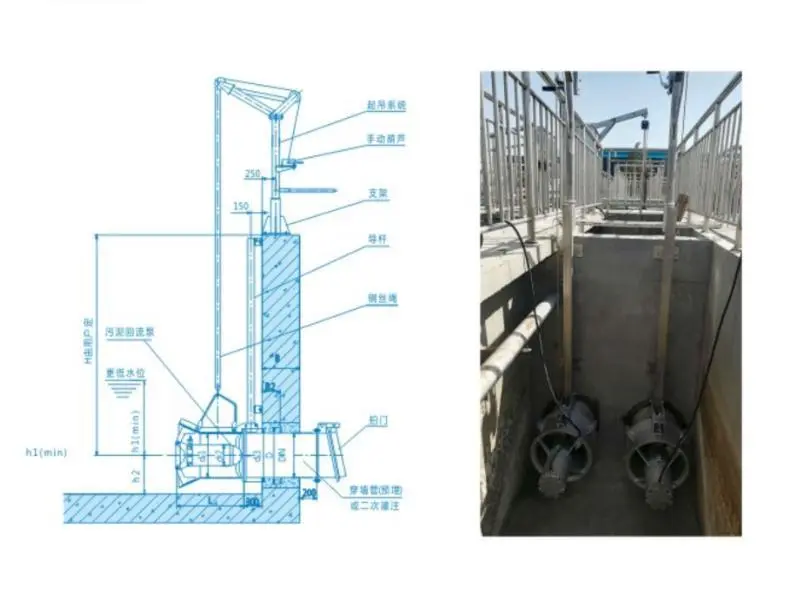

Model |

d1 |

d1 |

d1 |

D |

DN |

L |

h1 |

h2 |

B |

QJB-W1.5 |

195 |

440 |

520 |

600 |

400 |

680 |

750 |

350 |

Determined by user,Recommend larger than 400mm |

QJB-W2.5 |

195 |

440 |

520 |

600 |

400 |

680 |

750 |

350 |

|

QJB-W4 |

273 |

645 |

725 |

800 |

600 |

930 |

1200 |

550 |

|

QJB-W5 |

273 |

645 |

725 |

800 |

600 |

930 |

1200 |

550 |

|

QJB-W7.5 |

300 |

645 |

725 |

800 |

600 |

930 |

1200 |

550 |

|

QJB-W10 |

300 |

645 |

725 |

800 |

600 |

930 |

1200 |

550 |

|

QJB-W15 |

300 |

645 |

725 |

800 |

600 |

1130 |

1200 |

550 |

|

QJB-W18.5 |

300 |

645 |

725 |

800 |

600 |

1350 |

1300 |

550 |

Working Principle

The sludge recirculation pump uses a motor to drive the impeller, generating centrifugal force to draw sludge from the sedimentation tank into the pump body and transport it to the biological treatment unit. By adjusting the pump's flow rate, the sludge recirculation ratio can be controlled, optimizing wastewater treatment efficiency.

Features

1. Efficient Transport: Capable of stably and efficiently transporting high-concentration sludge.

2. Corrosion Resistance: The pump body and impeller are typically made of corrosion-resistant materials, suitable for wastewater treatment environments.

3. Low Maintenance: Simple structure, reliable operation, and low maintenance costs.

4. Adjustability: The flow rate can be adjusted according to process requirements, offering flexible operation.

Application Fields

1. Municipal Wastewater Treatment: Used for sludge recirculation in activated sludge processes.

2. Industrial Wastewater Treatment: Suitable for wastewater treatment systems in industries such as chemical, pharmaceutical, and food processing.

3. Environmental Engineering: Used in sludge treatment and resource utilization projects.

Selection and Maintenance

1. Selection: Choose the appropriate pump model based on sludge characteristics, flow rate requirements, and head requirements.

2. Maintenance: Regularly inspect the pump body, impeller, and sealing device, clear blockages, replace worn parts, and ensure long-term stable operation of the equipment.

The hyperboloid mixer is widely used in wastewater treatment, chemical, food, and pharmaceutical industries due to its efficient mixing, low energy consumption, and compact structure. Proper selection and regular maintenance are key to ensuring its long-term stable operation.