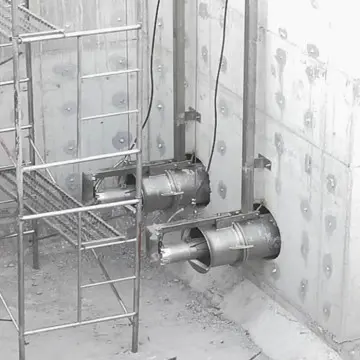

Peripheral Drive Sludge Mud Slurry Scraper for Waste Water Treatment

Description

This innovative machine allows sewage to seamlessly enter through a central pipe, where it's then skillfully distributed in the middle stable cylinder. As the water progresses towards the periphery, suspended solids begin a gradual descent, settling gracefully at the pool's bottom. Our scraper meticulously collects and channels these sediments into the central sink, facilitating their effortless discharge from the pool via water pressure, ensuring a clean and efficient treatment process.

Application

First, the use of the introduction

Our cutting-edge machine integrates several high-quality components for superior performance, including a robust motor, a state-of-the-art driving device, and a durable working bridge. Additional features include a central rotation mechanism, a dependable scraper hanger, and a sturdy scraper and bracket. The innovative design is completed with a functional mud bucket scraper and an intuitive on-site control box. For enhanced customization, we also offer stainless steel outlet weir plates and slag blocking devices as required, ensuring our machine meets all your wastewater treatment needs with precision.

Working bridge |

carbon steel anti-corrosion |

Walkway plate |

grid FRP plate |

Center Rotation Mechanism |

Component |

Basic Info.

Model NO. |

ZBGN peripheral drive full bridge mud scraper |

|

Type |

Separate |

Method |

Physical Treatment |

|

Usage |

Industrial |

Device Model |

Jg-10.3 |

|

Pool Diameter |

Ø10.30m |

Depth of Surrounding Pool |

5.10m |

|

Motor Power |

0.55kw IP55(with Gear Reducer) |

Transport Package |

Export Cases |

|

Specification |

customizable |

Trademark |

Lanjiang |

|

Origin |

No. 18 Xinyu Road, Liuhe District, Nanjing City |

HS Code |

8479820090 |

|

Production Capacity |

5000 Units/Year

|

Our transmission reducer is selected from top-tier domestic products, ensuring exceptional quality, unparalleled reliability, and an extended service life that stands the test of time.

Crafted with precision, the working bridge is a full-bridge fixed installation that boasts a remarkable deflection of less than 1/360 of the span. Meticulously welded using premium high-quality carbon steel and robust square pipes, it exemplifies structural integrity and durability.

Our central rotating mechanism is an engineering marvel, featuring a meticulously designed central support and turntable. The bearing is expertly chosen from standardized products, ensuring optimum performance. The lower section is seamlessly connected to the civil engineering infrastructure through durable welding or reliable bolting, guaranteeing stability and strength.