Rake-tooth rotary mechanical screen cleaner for hydropower station

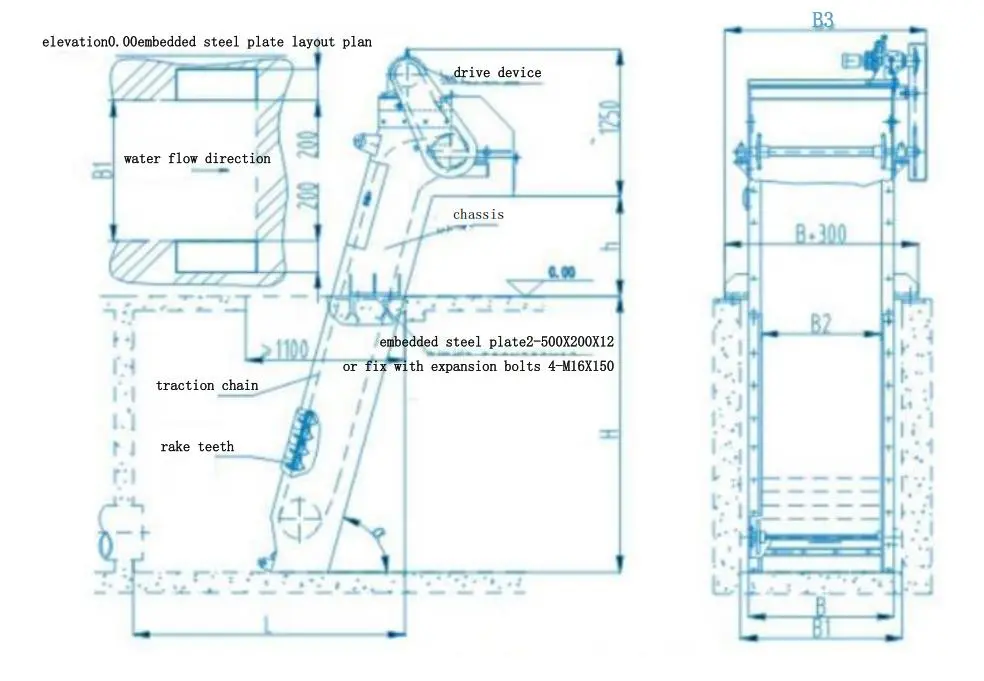

Main Structure

1. Screen Bars: Composed of parallel metal or plastic bars forming gaps to intercept solid debris.

2. Transmission Device: Includes motors, reducers, etc., driving the rotation of the screen bars.

3. Cleaning Device: Usually consists of rakes or brushes to remove debris from the screen bars.

4. Frame: Supports and secures the equipment.

5. Control System: Automatically or manually controls the start, stop, and operation of the equipment.

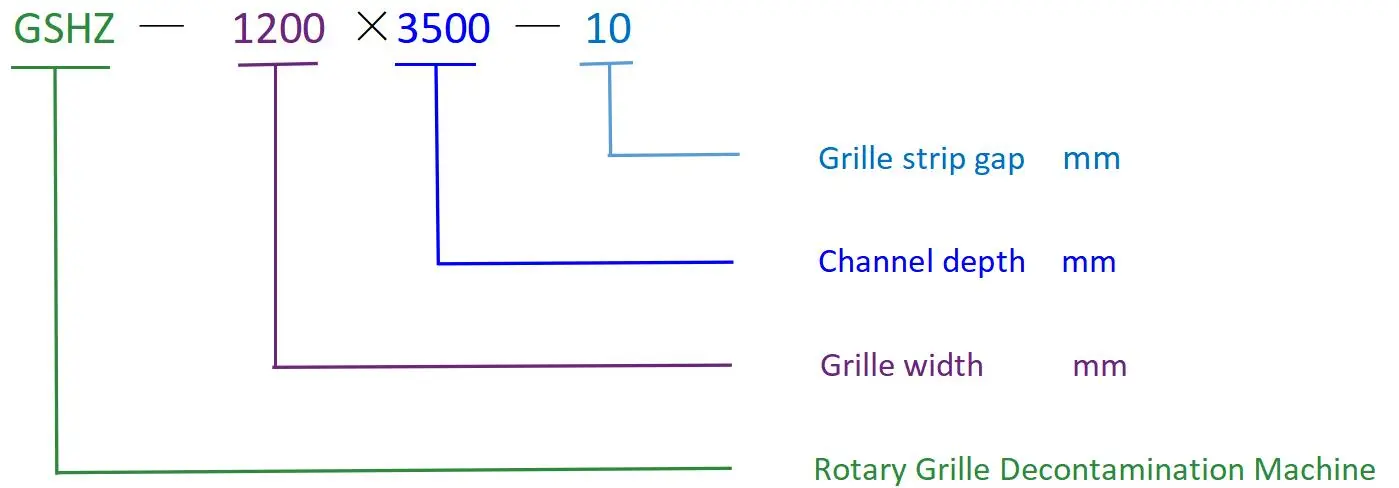

Model of Model Denotation

Technical parameters:

Device Width B |

300 |

400 |

500 |

600 |

700 |

800 |

900 |

1000 |

1100 |

1200 |

1300 |

1400 |

1500 |

|

Effective bar width B2 |

B2=B-160 |

|||||||||||||

total device width B3 |

B3=B+350 |

|||||||||||||

Effective grid gap |

2、3、5、10、20、30、40、50 |

|||||||||||||

rake chain speed |

About 2m/min |

|||||||||||||

Motor power kw |

0.37~0.75 |

0.55~1.1 |

0.75~1.5 |

1.1~2.2 |

1.5~3 |

|||||||||

Installation angle α |

60°、65°、70°、75°、80° |

|||||||||||||

Pool Width B1 |

B1≥B+70 |

|||||||||||||

Pool depth H |

500~15000 |

|||||||||||||

Slagging height h |

400~1500(According to the routine600) |

|||||||||||||

Description of necessary parameters for selection:

Necessary: width of channel (or width of equipment) B, depth H of channel, gap b of grille,material requirements of rake teeth, material requirements of frame. If there is no special description, as usual: installation angle 75°, slag discharge height 600MM, power standard, plate thickness standard

Structure diagram of GSHZ type rotary grille decontamination machine:

Model:GSHP |

300 |

400 |

500 |

600 |

700 |

800 |

900 |

1000 |

1100 |

1200 |

1250 |

1500 |

Water level before grille m |

1 |

|||||||||||

Fluid velocity m/s |

0.5~1.0 |

|||||||||||

3 |

3700- 7400 |

4100- 8200 |

5700- 14400 |

7500- 15000 |

9000- 18000 |

10600-21200 |

12300-24600 |

14000-28000 |

15500-31000 |

17200- 34400 |

18000-36000 |

22000- 44000 |

5 |

4500- 9000 |

5200- 10400 |

7100- 14200 |

9200- 18400 |

11200-22400 |

13000-26000 |

15000-30000 |

17400-34800 |

19400-38800 |

21000- 42000 |

22500-45000 |

24000- 48000 |

10 |

5300- 10600 |

6200- 12300 |

8800- 17600 |

11000-22000 |

13500-27000 |

16000-32000 |

17400-34800 |

21100-42200 |

24000-48000 |

25000- 50000 |

26000-52000 |

27000- 54000 |

20 |

5500- 11000 |

6650- 13000 |

9000- 18000 |

11500-23000 |

14000-28000 |

17000-34000 |

19000-38000 |

22000-44000 |

25000-50000 |

27000- 54000 |

28000-56000 |

29000- 58000 |

30 |

7100- 14200 |

8600- 17200 |

11700-23400 |

14900-29800 |

18200-36400 |

22100-44200 |

24700-49400 |

28600-57200 |

32500-65000 |

35700- 70200 |

36400-72800 |

37700- 75400 |

40 |

7800- 15500 |

10200- 20500 |

14500-29000 |

18800-37500 |

23000-46000 |

27000-54000 |

31500-63000 |

36000-72000 |

40000-80000 |

44000- 88000 |

46000-92000 |

57000- 115000 |

50 |

10200-20400 |

13250- 26500 |

18850-37700 |

24450-48900 |

29900-59800 |

35100-70200 |

40950-41900 |

46800-93600 |

52000-104000 |

57200- 114400 |

59800-119600 |

47100- 148200 |

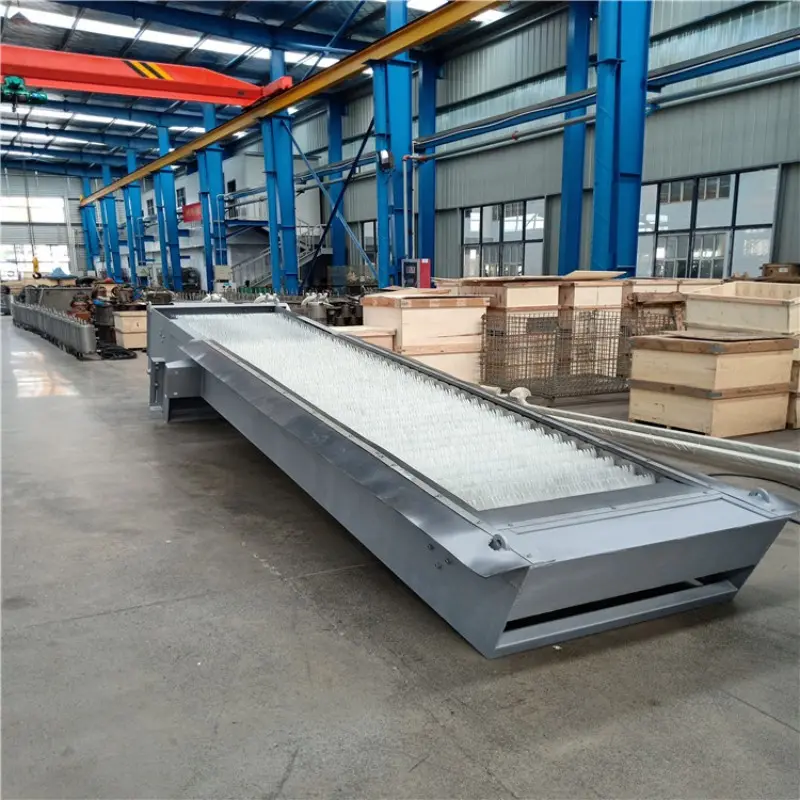

Working Principle

As wastewater flows through the screen bars, solid debris is intercepted. The rotating screen bars lift the debris to the top, where the cleaning device removes it, depositing the debris into a collection bin or conveyor, allowing the treated water to continue flowing.

Features

1. Automation: Capable of continuous operation and automatic debris removal.

2. High Efficiency: High interception efficiency, reducing blockages in subsequent equipment.

3. Durability: Made from corrosion-resistant materials, suitable for harsh environments.

4. Easy Maintenance: Simple structure, easy to maintain.

Application Areas

Widely used in municipal sewage treatment, industrial wastewater treatment, pumping stations, water plants, etc.

Selection and Maintenance

When selecting, consider treatment capacity, gap size, installation environment, etc. Regular inspections, cleaning, and lubrication are key to maintaining efficient operation.