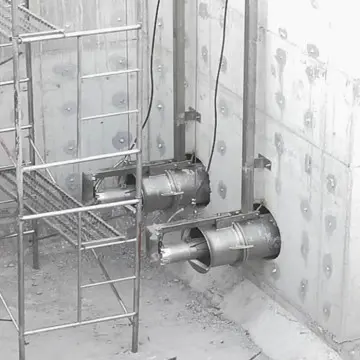

Rapid oxygenation submersible centrifugal aerator for aquaculture

Main Components

1. Motor: Provides power to drive the impeller at high speed.

2. Impeller: The core component responsible for cutting air into fine bubbles.

3. Air Intake: The channel through which air is drawn in.

4. Casing: Protects the internal structure and guides the flow of water and bubbles.

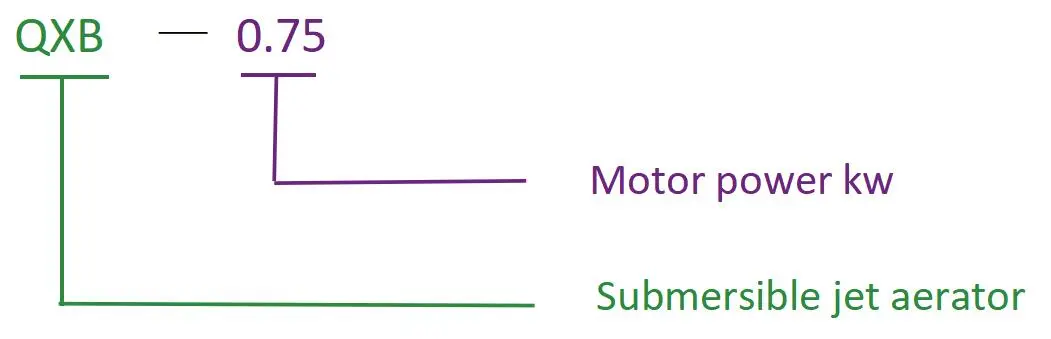

Model of Model Denotation

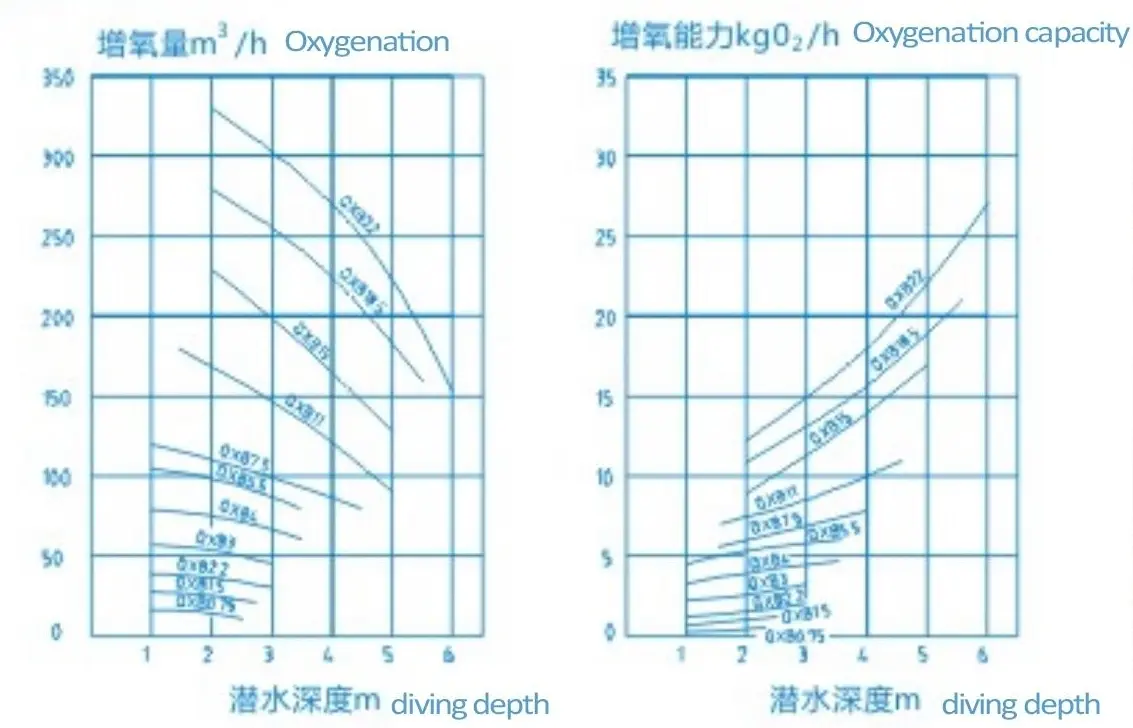

Performance parameters

Model |

QXB0.75 |

QXB1.5 |

QXB2.2 |

QXB3 |

QXB4 |

QXB5.5 |

QXB7.5 |

QXB11 |

QXB15 |

QXB18.5 |

QXB22 |

Power KW |

0.75 |

1.5 |

2.2 |

3 |

4 |

5.5 |

7.5 |

11 |

15 |

18.5 |

22 |

current A |

2.4 |

4 |

5.8 |

7.8 |

9.8 |

12.4 |

17 |

24 |

32 |

39 |

45 |

Voltage V |

380 |

||||||||||

Speed r/min |

1470 |

||||||||||

Frequency Hz |

50 |

||||||||||

Insulation level |

F |

||||||||||

Dive depth m |

1.5 |

2 |

3 |

3.5 |

4 |

4.5 |

5 |

5 |

5 |

5.5 |

6 |

|

Air Intake volume m³/h |

10 |

22 |

35 |

50 |

75 |

85 |

100 |

160 |

200 |

260 |

320 |

Aeration volume of clean water under standard conditions kgO2/h |

0.37 |

1 |

1.8 |

2.75 |

3.8 |

5.3 |

8.2 |

13 |

17 |

19 |

24 |

Service diameter M |

2.9 |

4 |

5.3 |

6.3 |

7.2 |

8.6 |

10.6 |

11.8 |

12.8 |

13.5 |

15 |

Dimensions of centrifugal submersible aerator

Model |

QXB1.5 |

QXB2.2 |

QXB3 |

QXB4 |

QXB5.5 |

QXB7.5 |

QXB11 |

QXB15 |

QXB18.5 |

QXB22 |

H |

630 |

630 |

630 |

655 |

815 |

815 |

1045 |

1045 |

1100 |

1100 |

B |

560 |

560 |

560 |

620 |

780 |

780 |

870 |

870 |

1050 |

1050 |

DN |

50 |

50 |

50 |

50 |

50 |

50 |

100 |

100 |

125 |

125 |

Working Principle

1. Air Intake: The motor drives the impeller to rotate at high speed, creating a negative pressure at the center of the impeller, which draws air in through the intake.

2. Bubble Cutting: The incoming air is cut into fine bubbles by the action of the impeller.

3. Bubble Dispersion: The fine bubbles are evenly dispersed into the water, increasing the contact area between oxygen and water, thus improving oxygen dissolution efficiency.

Features

1. High Oxygenation Efficiency: Enhances oxygen transfer efficiency through fine bubbles, providing significant oxygenation effects.

2. Energy-saving and Environmentally Friendly: Low energy consumption and stable operation, suitable for long-term continuous use.

3. Easy Installation: Compact structure, easy to install and maintain.

4. Wide Applicability: Can be used in various water environments such as sewage treatment plants, aquaculture ponds, lakes, and rivers.

Application Fields

1. Sewage Treatment: Provides oxygen required by microorganisms in processes like the activated sludge method.

2. Aquaculture: Increases dissolved oxygen in water bodies, improving the aquaculture environment and promoting fish growth.

3. Water Body Restoration: Used for ecological restoration of lakes, rivers, and other water bodies to improve water quality.

Selection and Maintenance

1. Selection: Choose the appropriate model and power based on factors such as water volume, oxygen demand, and working environment.

2. Maintenance: Regularly inspect components like the motor and impeller, and promptly clean any blockages to ensure proper operation.

With its advantages of high efficiency, energy savings, and easy installation, the centrifugal aerator has been widely adopted in the field of water treatment.