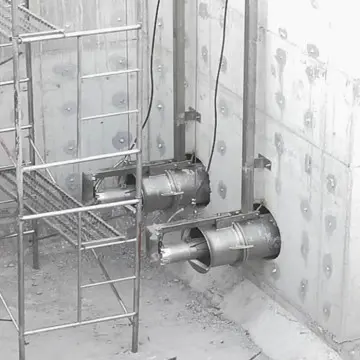

Self-priming submersible jet aerator for river channel management

Structure and Components

The Submersible Jet Aerator mainly consists of the following parts:

1.Submersible Motor: Provides power to drive the impeller at high speed.

2.Impeller: Rotates at high speed to generate negative pressure, sucking in air and creating a high-speed jet.

3.Mixing Chamber: Thoroughly mixes air and water.

4.Nozzle: Ejects the mixed air-liquid mixture in the form of a high-speed jet.

5.Air Intake Pipe: Used to draw in air, usually equipped with an air filter.

6.Mounting Bracket: Used to fix the equipment, often adjustable in height and angle.

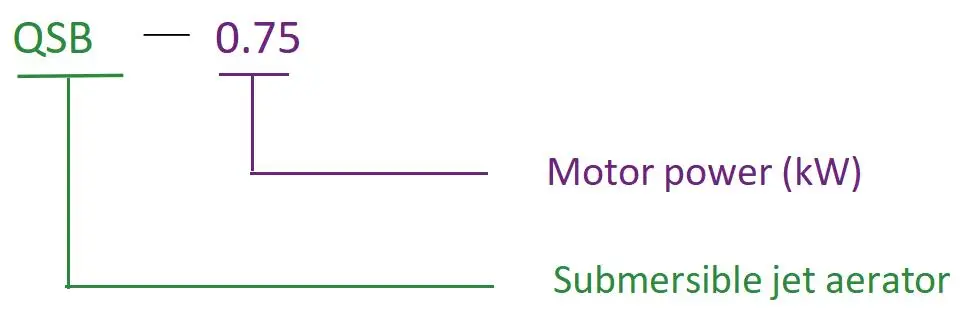

Model of Model Denotation

Technical Parameters

Model |

QSB0.75 |

QSB1.5 |

QSB2.2 |

QSB3 |

QSB4 |

QSB5.5 |

QSB7.5 |

Power KW |

0.75 |

1.5 |

2.2 |

3 |

4 |

5.5 |

7.5 |

current A |

2.9 |

3.7 |

5 |

6.4 |

8.2 |

12.4 |

16.3 |

Voltage V |

380 |

||||||

Speed r/min |

2900 |

2900 |

2900 |

2900 |

2900 |

1470 |

1450 |

Frequency Hz |

50 |

||||||

Insulation level |

F |

||||||

Dive depth m |

1.5 |

2 |

3.5 |

4 |

4.5 |

5 |

5.5 |

|

Air Intake volume m³/h |

10 |

22 |

35 |

50 |

75 |

85 |

100 |

Intake pipe mm |

32 |

32 |

50 |

50 |

50 |

50 |

50 |

Working Principle

1. Self-Priming Air: The high-speed rotation of the impeller generates negative pressure, drawing in air through the intake pipe.

2. Air-Liquid Mixing: Air and water are thoroughly mixed in the mixing chamber, forming an air-liquid mixture.

3. High-Speed Jet: The air-liquid mixture is ejected through the nozzle in the form of a high-speed jet, creating intense agitation and aeration.

4. Oxygenation and Mixing: The jet carries oxygen deep into the water while pushing water flow, achieving uniform aeration and mixing.

Technical Features

1.Efficient Oxygenation: Thoroughly dissolves oxygen into water through high-speed jets, ensuring high oxygenation efficiency.

2.Self-Priming Air: No external air source is required, as the device has a built-in air intake function, saving energy.

3.Strong Mixing Capability: High-speed jets promote water flow, achieving uniform mixing.

4.Low Noise: Operates underwater with low noise, minimizing environmental impact.

5.Flexible Installation: Can be adjusted in position and angle to suit different working conditions.

6.Corrosion Resistance: Key components are made of stainless steel or corrosion-resistant materials, suitable for wastewater environments.

Application Fields

1.Wastewater Treatment: Used in aeration processes such as activated sludge and oxidation ditches.

2.River Management: Improves river water quality, increases dissolved oxygen, and promotes ecological restoration.

3.Lake Restoration: Used for aeration and mixing in eutrophic lakes to inhibit algae growth.

4.Aquaculture: Increases dissolved oxygen in aquaculture water, improving stocking density and survival rates.

5.Industrial Wastewater Treatment: Used for aeration and mixing in high-concentration organic wastewater treatment.

Installation and Maintenance

1. Installation

- The equipment is usually fixed to the bottom or side of the water body using a bracket.

- Ensure the equipment is level during installation to avoid tilting that may affect performance.

- Use waterproof connectors for power cables to ensure safety.

2. Maintenance

- Regular Inspection: Check the impeller, nozzle, and motor operation status.

- Cleaning and Maintenance: Regularly clean the air intake pipe and filter to prevent clogging.

- Lubrication: Regularly lubricate motor bearings to extend service life.

- Shutdown Protection: When not in use for extended periods, remove the equipment from the water and clean it.

The Submersible Jet Aerator is widely used in water treatment and environmental restoration due to its efficient oxygenation, deep water applicability, and low noise characteristics.