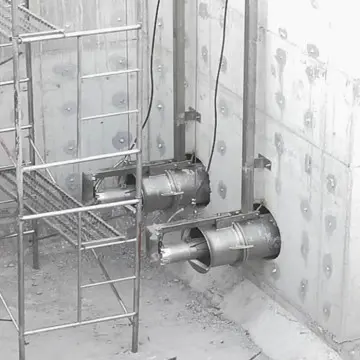

Stainless steel paddle mixer sewage treatment equipment

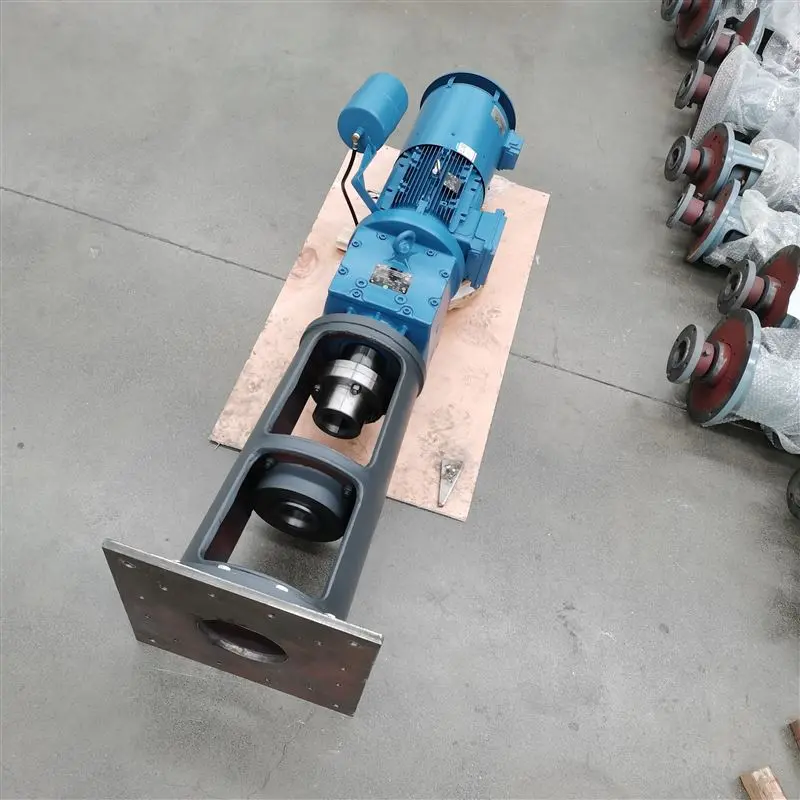

Structure

1. Motor: Provides power.

2. Mixing Shaft: Connects the motor and the paddle, transmitting power.

3. Paddle: Directly contacts the material, responsible for stirring, with various shapes such as flat paddles, inclined paddles, and spiral paddles.

4. Support Frame: Supports the equipment, ensuring stable operation.

5. Control System: Adjusts mixing speed and operation time.

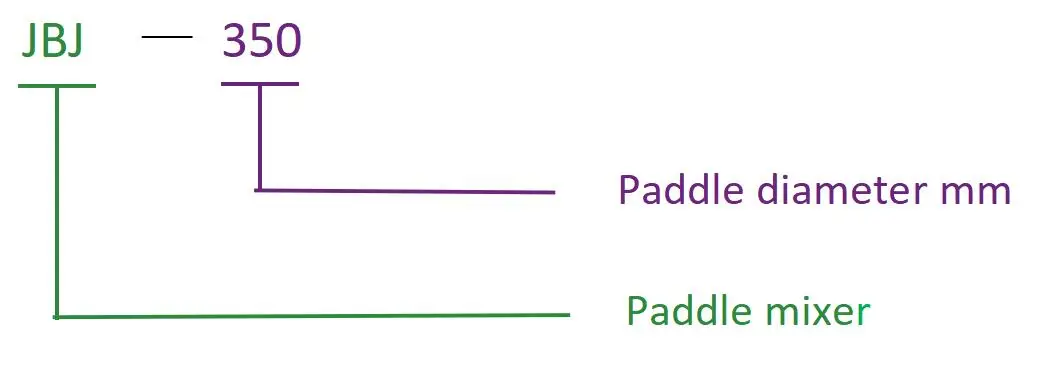

Model of Model Denotation

Main technical parameters and installation dimensions

Main parameters |

JBJ-350 |

JBJ-450 |

JBJ-600 |

JBJ-400 |

JBJ-600 |

JBJ-800 |

JBJ-550 |

JBJ-700 |

JBJ-900 |

Rotation speed(r/min) |

88 |

52 |

35 |

88 |

52 |

35 |

88 |

52 |

35 |

Motor power (kw) |

0.37 |

0.55 |

0.75 |

1.1 |

|||||

Lmm |

1500 |

||||||||

Dmm |

350 |

450 |

600 |

400 |

600 |

800 |

550 |

700 |

800 |

D1mm |

100 |

||||||||

D2mm |

175 |

||||||||

D3mm |

210 |

||||||||

n*d mm |

4*φ19 |

||||||||

Working Principle

The motor drives the mixing shaft to rotate, which in turn drives the paddle to move, causing the material to mix and stir within the container, achieving a homogenizing effect.

Features

1. Simple Structure: Easy to operate and maintain.

2. Strong Adaptability: Suitable for various materials.

3. Customizable: Paddles and speed can be adjusted according to requirements.

4. Efficient Mixing: Ensures uniform mixing of materials.

Application Fields

1. Chemical Industry: Used in reaction kettles, mixing tanks, etc.

2. Food Industry: Used for blending, emulsifying, and homogenizing.

3. Pharmaceutical Industry: Used for drug mixing and homogenizing.

4. Environmental Protection: Used for mixing and stirring in wastewater treatment.

Selection and Maintenance

1. Selection: Choose the appropriate model based on material characteristics, container size, and process requirements.

2. Maintenance: Regularly inspect the motor, mixing shaft, and paddle, replace worn parts in time, and keep the equipment clean.

Paddle mixers, with their simple structure, efficient mixing, and wide applicability, have become important equipment in multiple industries. Proper selection and maintenance can ensure their long-term stable operation.

about us

Nanjing Lanjiang Pump Industry Co., Ltd. is a professional manufacturer dedicated to the design, research and development, production and sales of sewage treatment equipment.The company is located in Xinhuang Industrial Park, Liuhe District, Jiangsu Province, China.Selected as a famous scientific and technological enterprise in Jiangsu Province and an advanced unit in Liuhe District.