Stainless steel QJB submersible mixer for sewage plant

Conditions Of Application

In order to ensure the normal operation of the submersible mixer,please make correct selection of the operating environment .

1.The highest temperature of the medium shall not exceed 40℃

2.The scope of pH value of the medium:5~9

3.Medium density of not more than 1150 kg/m³

4.Diving depth in general not more than 20 m when at the long-term diving operation.

Key matters need attention

The submersible mixer must completely submerse in the water and cannot operate in the inflammable,explosive, highly corrosive and high-temperature environment

The steel expansion bolts must be fixed as required, and the cables must be tightened and fixed after installation. All use polyurethane impeller, helical gearbox reducer.

Characteristics

1 . Compact structure, simple operation and maintenance, convenient installation and maintenance, and long service life;

2. The impeller has a reasonable hydraulic design structure, high working efficiency, and the swept-back blade has a self-cleaning function, which can prevent debris from being entangled and blocked;

3. Mixed use with aeration system can greatly reduce energy consumption, significantly increase oxygenation, and effectively prevent precipitation;

4. The motor winding insulation grade is F, the protection grade is IP68, and NSK/SKF bearings are used. The motor can be equipped with an anti-condensation device. The motor uses an over-temperature protection device to make the motor work more reliably;

5. Two mechanical seals; the mechanical seal is sealed with tungsten carbide material, and the rubber material is fluorine rubber

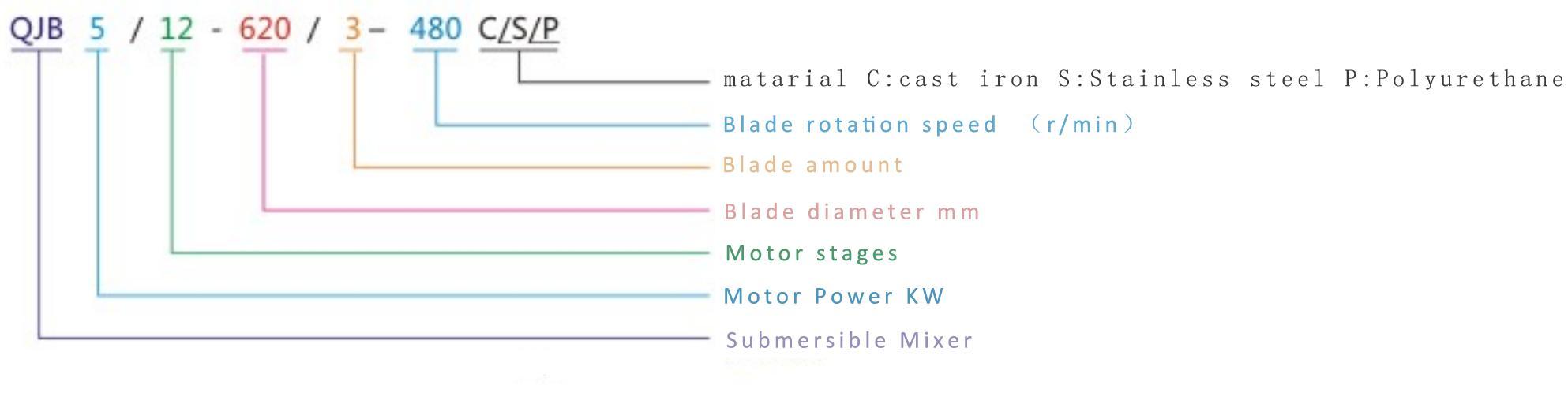

Model of Model Denotation

Performance parameters

The mixer operates under the conditions of rated voltage 380V, frequency 50Hz, winding insulation grade F, protection grade IP68, and working standard I.

Model |

Power (kW) |

Current(A) |

Impeller diameter (mm) |

Impeller Speed (r/min) |

Thrust (N) |

Weight (kg) |

Install system |

|

Cast mixer |

QJB0.85/8-260/3-740/C/S |

0.85 |

3.2 |

260 |

740 |

163 |

65 |

System I |

QJB1.5/6-260/3-980/C/S |

1.5 |

4 |

260 |

980 |

290 |

65 |

System I |

|

QJB2.2/8-320/3-740/C/S |

2.2 |

5.9 |

320 |

740 |

582 |

70 |

System I |

|

QJB4/6-320/3-960/C/S |

4 |

10.3 |

320 |

960 |

609 |

70 |

System I |

|

QJB5.5/8-640/3-232/C/S |

5.5 |

13.5 |

640 |

232 |

1800 |

230 |

System Ⅱ |

|

QJB7.5/6-640/3-303/C/S |

7.5 |

17.5 |

640 |

303 |

2600 |

275 |

System Ⅱ |

|

QJB11/6-790/3-303/C/S |

11 |

25.4 |

790 |

303 |

2900 |

200 |

System II/III |

|

QJB15/6-790/3-368/C/S |

15 |

34.5 |

790 |

368 |

3540 |

270 |

System II/III |

|

Stamping mixer |

QJB0.37/6-230/3-980/C/S |

0.37 |

2.5 |

230 |

980 |

138 |

30 |

System I/II |

QJB0.55/4-230/3-1400 |

0.55 |

2.5 |

230 |

1450 |

145 |

30 |

System I/II |

|

QJB0.85/8-260/3-740/C |

0.85 |

4 |

260 |

740 |

163 |

55 |

System II/II |

|

QJB1.5/6-260/3-980/C |

1.5 |

4 |

260 |

980 |

290 |

55 |

System II/II |

|

QJB1.5/8-400/3-740/S |

1.5 |

5.4 |

400 |

740 |

600 |

78 |

System I |

|

QJB2.5/8-400/3-740/S |

2.5 |

9 |

400 |

740 |

800 |

80 |

System I |

|

QJB3/8-400/3-740/S |

3 |

11 |

400 |

740 |

920 |

90 |

System Ⅱ |

|

QJB4/6-400/3-980/S |

4 |

12 |

400 |

980 |

1200 |

95 |

System Ⅱ |

|

QJB4/12-620/3-480/S |

4 |

14 |

620 |

480 |

1400 |

230 |

System III |

|

QJB5/12-620/3-480/S |

5 |

18.2 27 |

620 |

480 |

1800 |

230 |

System II |

|

QJB7.5/12-620/3-480/S |

7.5 |

620 |

480 |

2600 |

275 |

System II |

||

QJB10/12-620/3-480/S |

10 |

32 |

620 |

480 |

3300 |

260 |

System III |

|

QJB15/12-620/3-480/S |

15 |

34 |

620 |

480 |

3460 |

275 |

System II |

|

QJB18.5/12-620/3-480/S |

18.5 |

41 |

620 |

480 |

4200 |

290 |

System II |

|

QJB22/12-620/3-480/S |

22 |

47 |

620 |

480 |

5400 |

310 |

System II |

|

Low speed push flow mixer |

QJB1.5/4-1100/2-85/P |

1.5 |

4 |

1100 |

85 |

860 |

170 |

System IV |

QJB1.5/4-1400/2-36/P |

1.5 |

4 |

1400 |

36 |

860 |

175 |

System IV |

|

QJB1.5/4-1800/2-42/P |

1.5 |

4 |

1800 |

42 |

1480 |

236 |

System IV |

|

QJB2.2/4-1400/2-42/P |

2.2 |

5.3 |

1400 |

48 |

1430 |

180 |

System IV |

|

QJB2.2/4-1800/2-42P |

2.2 |

5.3 |

1800 |

42 |

1100 |

185 |

System IV |

|

QJB3/4-1100/2-115P |

3 |

6.8 |

1100 |

115 |

1500 |

175 |

System IV |

|

QJB3/4-1400/2-56P |

3 |

6.8 |

1400 |

63 |

1870 |

183 |

System IV |

|

QJB3/4-1800/2-56P |

3 |

6.8 |

1800 |

56 |

2040 |

186 |

System IV |

|

QJB4/4-1400/2-56P |

4 |

9.2 |

1800 |

56 |

2150 |

170 |

System IV |

|

QJB4/4-1800/2-63P |

4 |

9.2 |

1800 |

63 |

2710 |

190 |

System IV |

|

QJB4/4-2500/2-42P |

4 |

9.2 |

2500 |

42 |

3200 |

220 |

System IV |

|

QJB5/4-1800/2-63P |

5 |

11.9 |

1800 |

63 |

3320 |

200 |

System IV |

|

QJB5/4-2500/2-56P |

5 |

11.9 |

2500 |

56 |

3840 |

240 |

System IV |

|

QJB7.5/4-1800/2-63P |

7.5 |

15.2 |

2500 |

63 |

4010 |

260 |

System IV |

|

QJB7.5/4-2500/2-63P |

7.5 |

15.2 |

2500 |

63 |

4280 |

280 |

System IV |

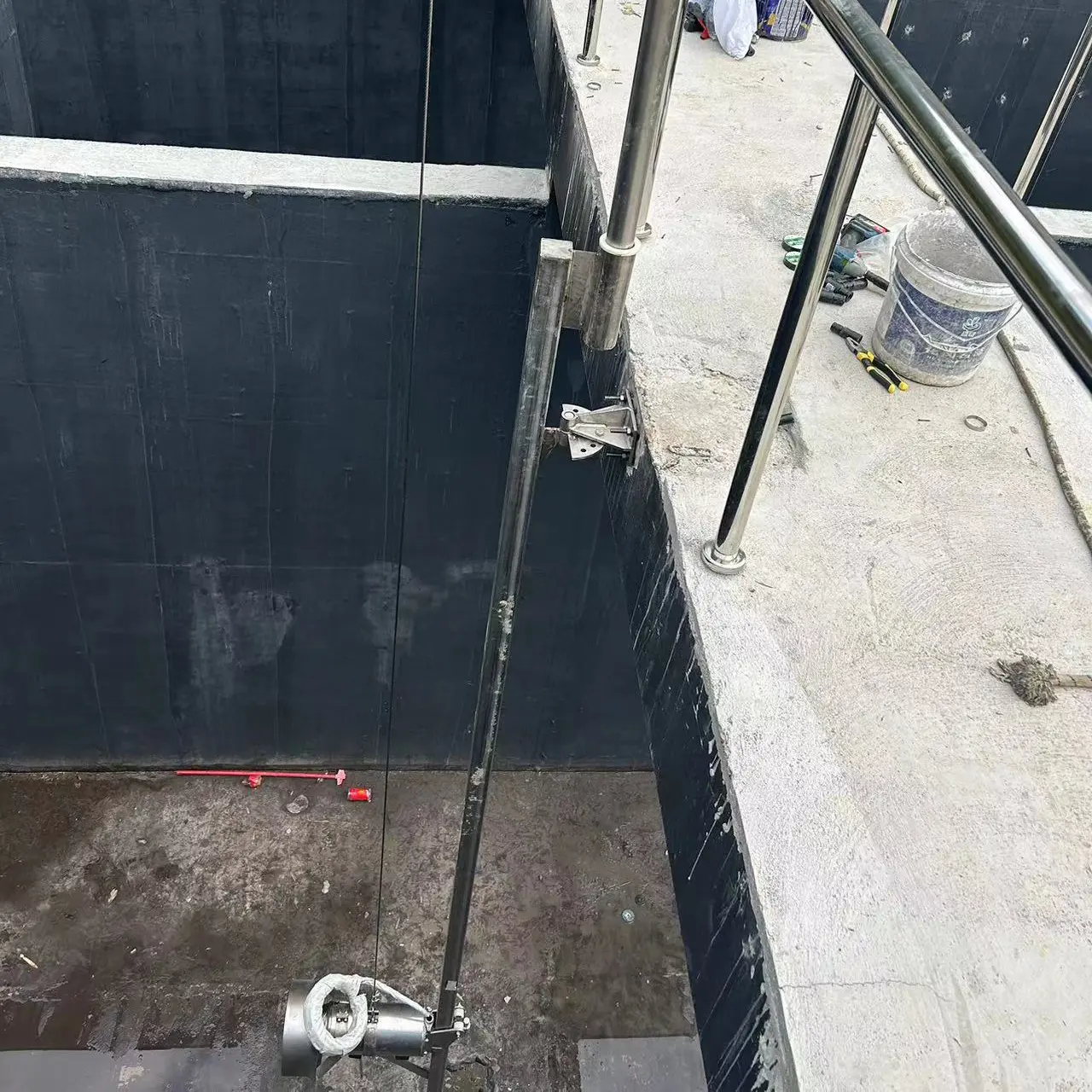

Installation method and size

Submersible mixers can be installed in a variety of ways,Here are more general ways to choose from,Please refer to the table below for dimensions.Our company can also make special designs according to user requirements.

Device model |

a |

D |

b |

L |

H1min |

H2min |

Install system |

QJB0.85/8-260/3-740/C/S |

φ60□50 |

360 |

250/330 |

529/630 |

500 |

110 |

I/II |

QJB1.5/6-260/3-960/C/S |

φ60□50 |

360 |

250/330 |

529/630 |

500 |

110 |

I/II |

QJB2.2/8-320/3-740/C/S |

□70 |

460 |

320 |

970 |

800 |

150 |

II |

QJB4/6-320/3-960/C/S |

□70 |

460 |

320 |

970 |

800 |

150 |

II |

QJB0.37/4-230/3-980/S |

φ60□40 |

360 |

250/330 |

610/620 |

500 |

110 |

I/II |

QJB0.55/4-230/3-1450/S |

φ60□40 |

360 |

250/330 |

610/620 |

500 |

110 |

I/II |

QJB0.85/8-260/3-740/S |

φ60□50 |

360 |

250/330 |

580/740 |

500 |

110 |

I/II |

QJB1.5/6-260/3-980/S |

φ60□50 |

360 |

250/330 |

580/740 |

500 |

110 |

I/II |

QJB1.5/8-400/3-740 |

□70 |

530 |

300 |

940 |

800 |

200 |

II |

QJB2.5/8-400/3-740 |

□70 |

530 |

300 |

940 |

800 |

200 |

II |

QJB3/8-400/3-740 |

□70 |

530 |

300 |

940 |

800 |

200 |

II |

QJB4/6-400/3-980 |

□70 |

530 |

300 |

940 |

800 |

200 |

II |

QJB4/12-620/3-480 |

□100 |

820 |

320 |

1190 |

1100 |

300 |

II |

QJB5/12-620/3-480 |

□100 |

820 |

320 |

1190 |

1100 |

300 |

II |

QJB7.5/12-620/3-480 |

□100 |

820 |

320 |

1200 |

1500 |

300 |

II |

QJB10/12-620/3-480 |

□100 |

820 |

320 |

1200 |

1500 |

300 |

II |

QJB11/12-620/3-480 |

□100 |

820 |

320 |

1200 |

1500 |

300 |

II |

QJB15/12-620/3-480 |

□100 |

820 |

320 |

1250 |

1500 |

300 |

II |

QJB18.5/12-620/3-480/S |

□100 |

820 |

320 |

1380 |

1500 |

300 |

II |

QJB22/12-620/3-480 |

□100 |

820 |

320 |

1380 |

1500 |

300 |

II |

QJB1.5/4-1100/2-43/P/G |

□100 |

1100 |

150 |

1100 |

1000 |

280 |

II |

QJB2.2/4-1100/2-52/P/G |

□100 |

1100 |

150 |

1100 |

1000 |

280 |

II |

QJB3/4-1100/2-87/P/G |

□100 |

1100 |

150 |

1100 |

1000 |

280 |

II |

QJB4/4-1100/2-115/P |

□100 |

1100 |

150 |

1100 |

1000 |

280 |

II |

QJB2.2/4-1400/2-43/P |

□100 |

1400 |

150 |

1100 |

750 |

280 |

II |

QJB3/4-1400/2-63/P/G |

□100 |

1400 |

150 |

1100 |

750 |

280 |

II |

QJB4/4-1400/2-87/P/G |

□100 |

1400 |

150 |

1100 |

750 |

280 |

II |

QJB2.2/4-1600/2-38/P/G |

□100 |

1600 |

150 |

1100 |

800 |

280 |

II |

QJB3/4-1600/2-43/P/G |

□100 |

1600 |

150 |

1100 |

800 |

280 |

II |

QJB4/4-1600/2-52/P/G |

□100 |

1600 |

150 |

1100 |

800 |

280 |

II |

QJB2.2/4-1800/2-38/P/G |

□100 |

1800 |

150 |

1100 |

800 |

280 |

II |

QJB3/4-1800/2-43/P/G |

□100 |

1800 |

150 |

1100 |

800 |

280 |

II |

QJB4/4-1800/2-52/P/G |

□100 |

1800 |

150 |

1100 |

800 |

280 |

II |

QJB5/4-1800/2-63/P/G |

□100 |

1800 |

150 |

1100 |

800 |

280 |

II |

QJB2.2/4-2200/2-34/P/G |

□100 |

2200 |

150 |

1200 |

900 |

280 |

II |

QJB3/4-2200/2-38/P/G |

□100 |

2200 |

150 |

1200 |

900 |

280 |

II |

QJB4/4-2200/2-43/P/G |

□100 |

2200 |

150 |

1200 |

900 |

280 |

II |

QJB5/4-2200/2-52/P/G |

□100 |

2200 |

150 |

1200 |

900 |

280 |

II |

QJB2.2/4-2500/2-34/P/G |

□100 |

2500 |

150 |

1200 |

900 |

280 |

II |

QJB3/4-2500/2-38/P/G |

□100 |

2500 |

150 |

1200 |

900 |

280 |

II |

QJB4/4-2500/2-43/P/G |

□100 |

2500 |

150 |

1200 |

900 |

280 |

II |

QJB5/4-2500/2-45/P/G |

□100 |

2500 |

150 |

1200 |

900 |

280 |

II |

QJB4/4-1600/3-43/P/G |

□100 |

1600 |

150 |

1100 |

800 |

280 |

II |

QJB5/4-1600/3-52/P/G |

□100 |

1600 |

150 |

1100 |

800 |

280 |

II |

QJB4/4-1800/3-43/P/G |

□100 |

1800 |

150 |

1100 |

800 |

280 |

II |

QJB5/4-1800/3-52/P/G |

□100 |

1800 |

150 |

1100 |

800 |

280 |

II |

QJB7.5/4-1800/3-52/P/G |

□100 |

1800 |

150 |

1100 |

800 |

280 |

II |

QJB4/4-2500/3-38/P/G |

□100 |

2500 |

150 |

1200 |

900 |

280 |

II |

QJB5/4-2500/3-43/P/G |

□100 |

2500 |

150 |

1200 |

900 |

280 |

II |

QJB7.5/4-2500/3-52/P/G |

□100 |

2500 |

150 |

1200 |

900 |

280 |

II |

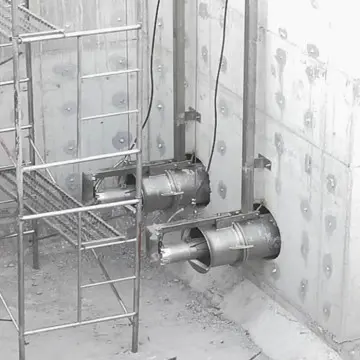

Floating Submersible Mixer operation

Submersible mixer operation

Submersible mixer