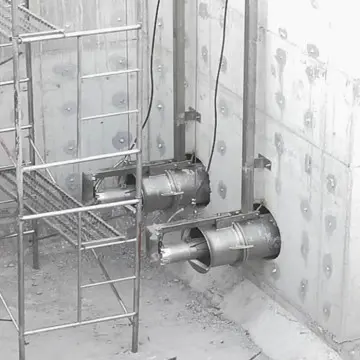

Stainless steel rotary rake grille slag machine for rainwater pump station

Working Principle

The device uses rotating rake teeth to scoop solid debris from the water. As the rake teeth move, the debris is lifted to the top and discharged through a scraper mechanism, achieving solid-liquid separation.

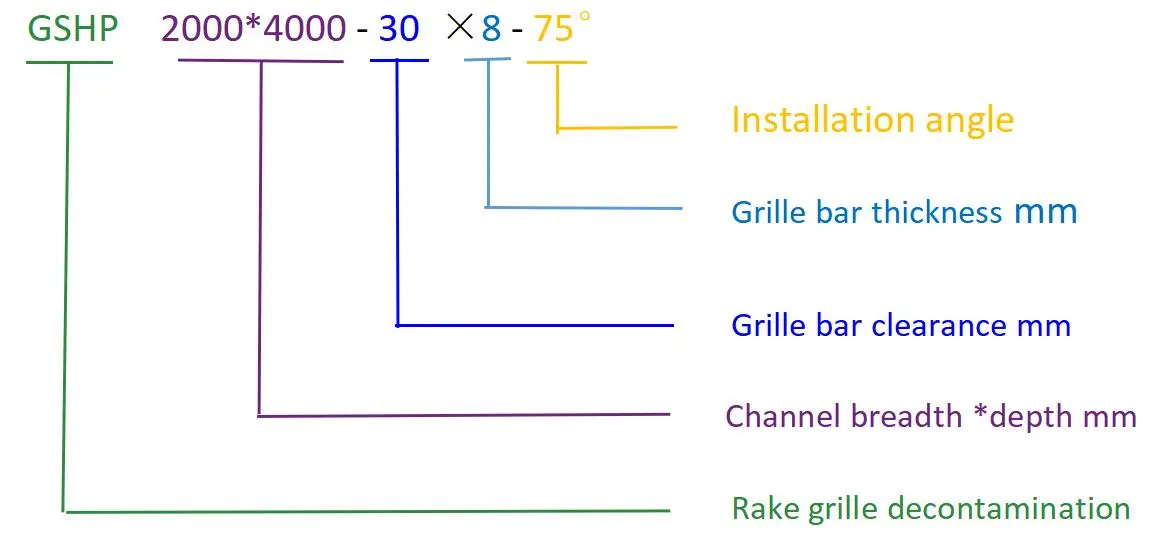

Model of Model Denotation

Main technical parameters and installation dimensions

Main parameters and dimensions |

Device Model GSHP |

|||||||||||

800 |

1000 |

1200 |

1400 |

1600 |

1800 |

2000 |

2200 |

2400 |

2600 |

2800 |

3000 |

|

Channel breadth B1 mm |

800 |

1000 |

1200 |

1400 |

1600 |

1800 |

2000 |

2200 |

2400 |

2600 |

2800 |

3000 |

Device width below channel B mm |

700 |

900 |

1100 |

1300 |

1500 |

1700 |

1900 |

2100 |

2300 |

2500 |

2700 |

2900 |

Total device width B2 mm |

1080 |

1280 |

1480 |

1680 |

1880 |

2080 |

2280 |

2480 |

2680 |

2880 |

3080 |

3280 |

Channel Depth H mm |

1000~15000(User defined) |

|||||||||||

Device height above the channel H mm |

h+1350 |

|||||||||||

Discharge port height h mm |

400~1500User defined,according to the routine,800 |

|||||||||||

Installation angle α |

60°、65°、70°、75°、80°(recommend 75°) |

|||||||||||

Grille bar clearance b mm |

10、15、20、30、40、50、60、80、100 |

|||||||||||

Motor power kw |

0.75~1.1 |

1.1~2.2 |

2.2~3 |

|||||||||

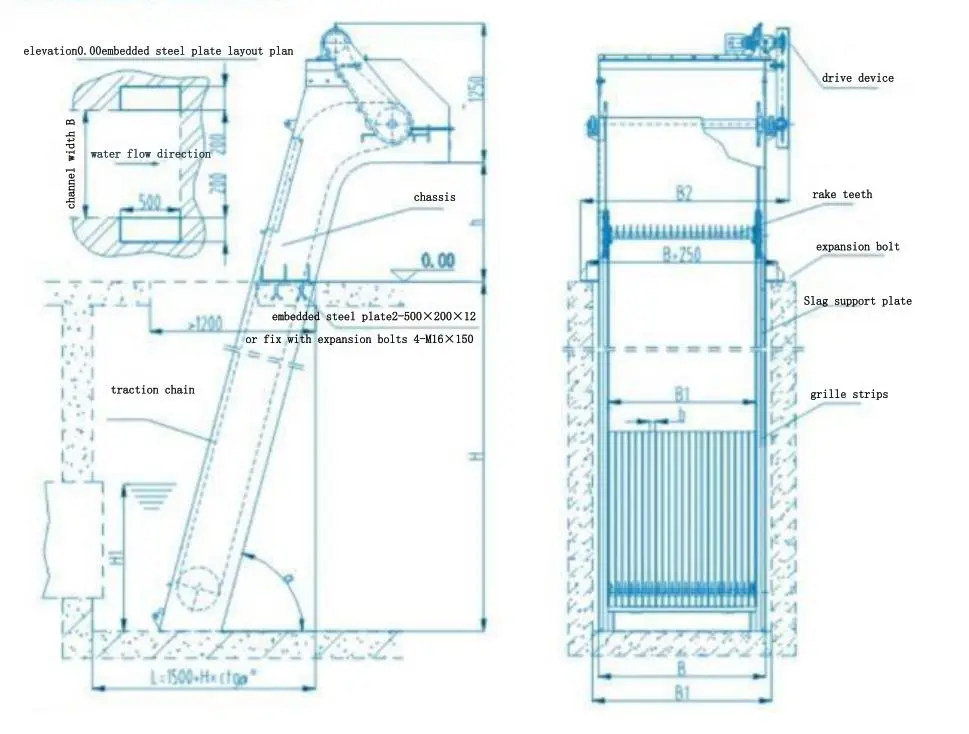

Description of necessary parameters for selection:

Channel width B, channel depth H, higher water level H1, grid spacing b, material requirements. Other non-required standard!

Outline drawing of rotary rake grille decontamination machine:

Water flow meter

Model:GSHP |

800 |

1000 |

1200 |

1400 |

1600 |

1800 |

2000 |

2200 |

2400 |

2600 |

2800 |

3000 |

Water level before grille m |

1 |

|||||||||||

Fluid velocity m/s |

1 |

|||||||||||

20 |

3.34 |

4.51 |

6.57 |

6.85 |

8.03 |

9.19 |

10.37 |

11.55 |

12.71 |

13.88 |

15.06 |

16.22 |

30 |

3.75 |

5.07 |

6.39 |

7.71 |

9.03 |

10.36 |

11.67 |

13 |

14.32 |

15.63 |

16.95 |

18.27 |

40 |

4 |

5.41 |

6.82 |

8.22 |

9.63 |

11.01 |

12.44 |

13.85 |

15.26 |

16.66 |

18.07 |

19.48 |

50 |

4.17 |

5.63 |

7.12 |

8.57 |

10.02 |

11.47 |

12.96 |

14.5 |

15.86 |

17.4 |

18.18 |

20.26 |

60 |

4.27 |

5.8 |

7.3 |

8.8 |

10.32 |

11.81 |

13.34 |

14.82 |

16.4 |

17.82 |

19.41 |

20.88 |

80 |

4.43 |

6.02 |

7.59 |

9.14 |

10.68 |

12.23 |

13.85 |

15.4 |

16.94 |

18.49 |

20.11 |

21.66 |

100 |

4.57 |

6.15 |

7.75 |

9.35 |

10.94 |

12.57 |

14.15 |

15.73 |

17.73 |

18.9 |

20.57 |

22.15 |

Illustrate:

If the control of the distributor is required, the conventional control is manual control. The electric control can be equipped with a PLC interface; it can be linked with other equipment; it can be controlled by time; it can be controlled by liquid level. When the accidental high water level occurs, the decontamination machine can be started immediately without the limitation of the cycle; the liquid level difference can be controlled. During the shutdown period, if the grille is accidentally blocked, when the water level difference before and after the grille reaches the set accident high water level, the removal of The dirt machine can be started immediately.

When the user needs it, it should be specified when ordering.

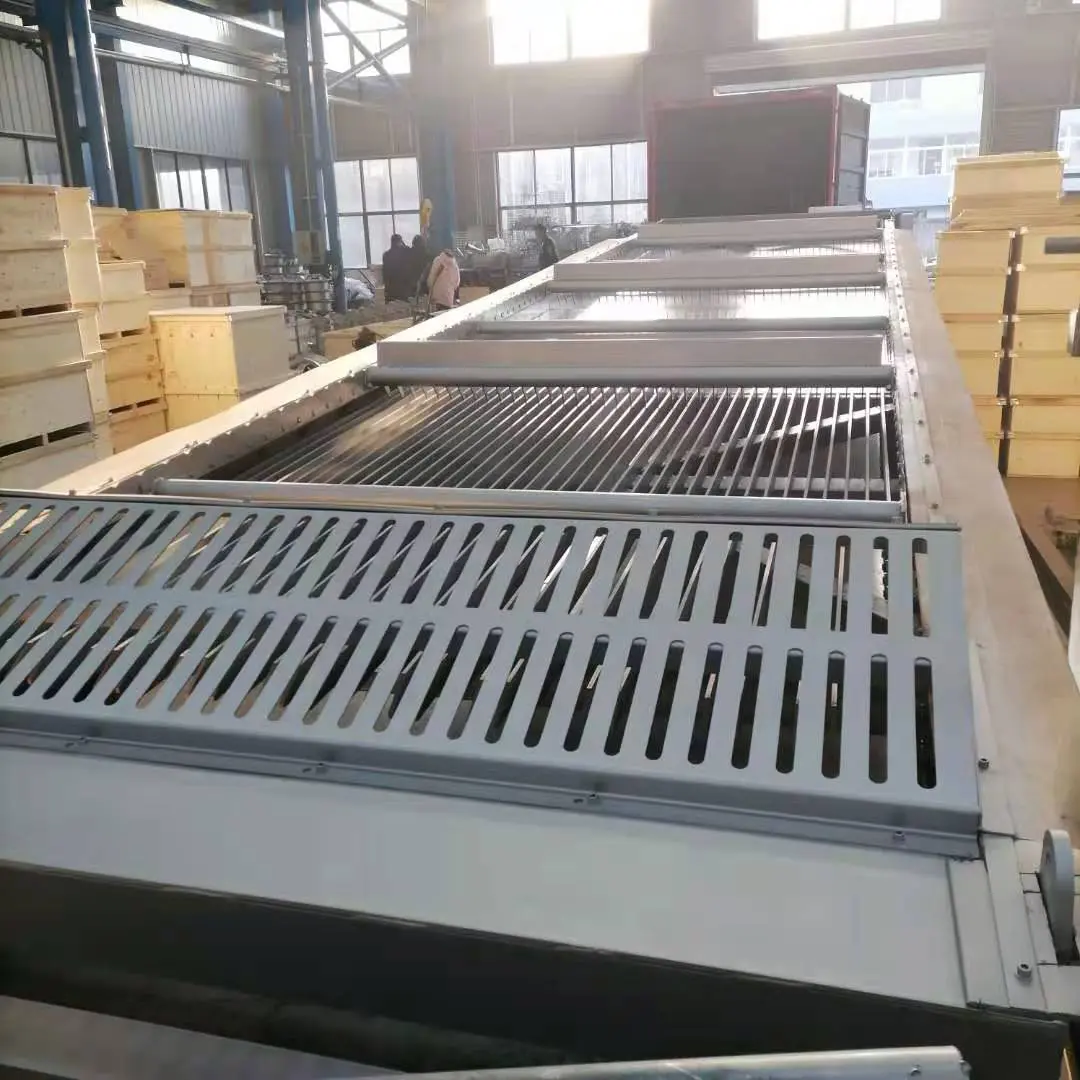

Main Components

1. Rake Teeth: Used to intercept and collect debris, typically made of stainless steel for corrosion resistance.

2. Drive Unit: Provides power to rotate the rake teeth.

3. Screen Bars: The fixed part of the device, used to intercept larger debris.

4. Discharge Mechanism: Removes the collected debris from the device.

Features

1. High Automation: Capable of continuous operation, automatically clearing debris with minimal manual intervention.

2. High Efficiency: Suitable for various water qualities, effectively intercepting suspended solids of different sizes.

3. Strong Corrosion Resistance: Main components are made of stainless steel or anti-corrosion materials, suitable for harsh water environments.

4. Stable Operation: Simple structure, low failure rate, and easy maintenance.

5. Wide Applicability: Widely used in sewage treatment plants, pumping stations, rivers, and other settings.

Applications

1. Municipal Sewage Treatment: Intercepting floating and suspended solids in sewage.

2. Industrial Wastewater Treatment: Pre-treating solid impurities in industrial wastewater.

3. Stormwater Treatment: Removing leaves, plastics, and other debris from stormwater.

4. River Cleaning: Clearing floating debris from rivers, lakes, and other water bodies.

Advantages

1. Efficient Interception: The gap between screen bars can be adjusted to accommodate debris of different sizes.

2. Energy-Efficient and Eco-Friendly: Low energy consumption during operation, reducing secondary pollution.

3. Easy Maintenance: Reasonable structural design, making it easy to disassemble and clean.