Stainless steel sand water separator for sewage treatment plants

Key Features

1. High-Efficiency Separation: Effectively separates sand and solid particles from water, improving water quality.

2. Automated Operation: Equipped with an automatic control system, making it easy to operate and reducing manual intervention.

3. Compact Structure: Designed with a compact structure, it occupies minimal space, making it suitable for areas with limited room.

4. High Durability: Constructed with wear-resistant materials, ensuring a long service life and low maintenance costs.

5. Eco-Friendly and Energy-Efficient: The separated sand can be recycled, reducing resource waste and meeting environmental standards.

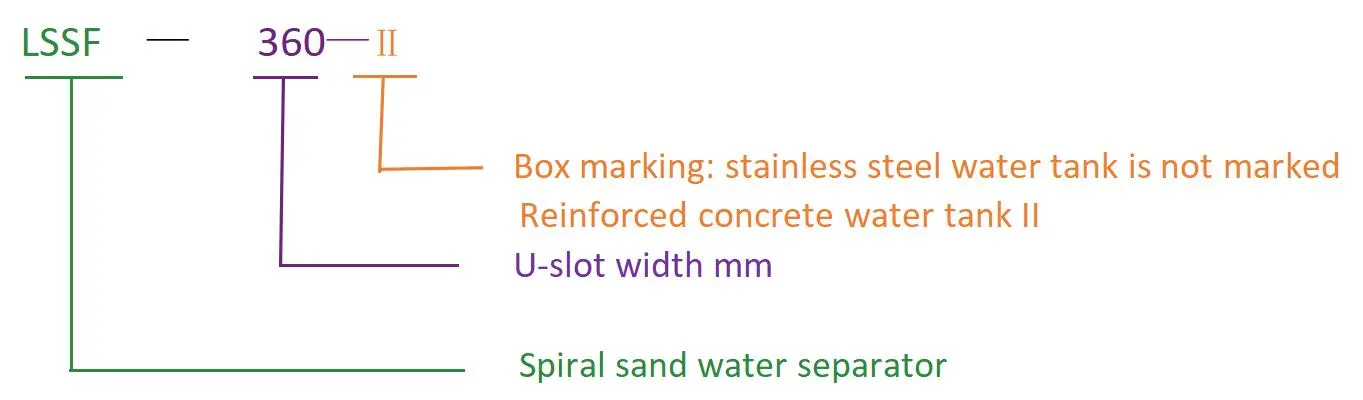

Model of Model Denotation

The main technical parameters

Parameters |

LSSF-260 |

LSSF-320 |

LSSF-355 |

LSSF-420 |

Processing capacity L/S |

5~12 |

12~20 |

20~27 |

27~35 |

Motor power kw |

0.37 |

0.37 |

0.75 |

0.75 |

Order requirements for spiral sand water separator

1. Write the full name according to the model representation;

2. Use environment (indoor, outdoor and others)

3. If the reinforced concrete water tank is used, the engineering design data of the relevant part should be provided.

Stainless steel water tank

Dimensions code |

LSSF-260 |

LSSF-320 |

LSSF-355 |

LSSF-420 |

L |

4350 |

4770 |

6350 |

6700 |

L1 |

3840 |

4380 |

5890 |

6290 |

L2 |

3000 |

4000 |

||

L3 |

1000 |

1500 |

2000 |

2500 |

W |

1653 |

1748 |

1880 |

1920 |

W1 |

1320 |

1420 |

1580 |

1880 |

W2 |

1200 |

1260 |

1420 |

1720 |

H |

2100 |

2350 |

3050 |

3250 |

H1 |

1670 |

1860 |

2480 |

2590 |

H2 |

1600 |

1800 |

2250 |

2250 |

B1 |

1260 |

1340 |

1506 |

1800 |

B2 |

326 |

406 |

441 |

506 |

A1 |

2700 |

2800 |

3900 |

3800 |

A2 |

100 |

|||

A3 |

130 |

|||

Water inlet diameter |

Φ100 |

Φ150 |

Φ200 |

Φ200 |

Overflow port diameter |

Φ150 |

Φ200 |

Φ250 |

Φ250 |

Concrete water tank

Dimensions code |

LSSF-260Ⅱ |

LSSF-320Ⅱ |

LSSF-355Ⅱ |

LSSF-420Ⅱ |

L |

4800 |

5300 |

7000 |

7400 |

L1 |

3000 |

4000 |

||

L2 |

1000 |

1500 |

2000 |

2500 |

W |

1200 |

1260 |

1420 |

1720 |

H |

500 |

550 |

800 |

1000 |

H1 |

600 |

700 |

700 |

850 |

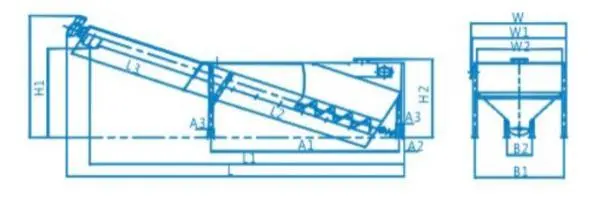

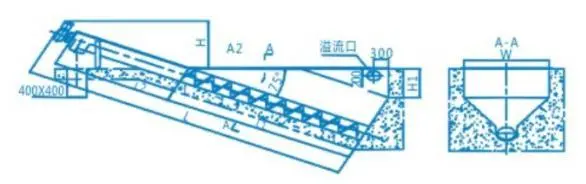

Outline installation dimension drawing

Dimensions code |

LSSF-260Ⅱ |

LSSF-320Ⅱ |

LSSF-355Ⅱ |

LSSF-420Ⅱ |

L |

4800 |

5300 |

7000 |

7400 |

L1 |

3000 |

4000 |

||

L2 |

1000 |

1500 |

2000 |

2500 |

W |

1200 |

1260 |

1420 |

1720 |

H |

500 |

550 |

800 |

1000 |

H1 |

600 |

700 |

700 |

850 |

LSSF type spiral sand water separator outline drawing (stainless steel water tank)

LSSFⅡ type spiral sand-water separator outline drawing (concrete water tank)

Working Principle

1. Inlet: Sand-laden wastewater enters the separator through the inlet.

2. Separation: As the wastewater flows inside the separator, sand particles settle to the bottom due to gravity.

3. Transport: A screw conveyor transports the settled sand from the bottom to the discharge outlet.

4. Discharge: The separated clean water is discharged from the outlet, either moving to the next treatment stage or being released directly.

Applications

1. Sewage Treatment Plants: Used in the preliminary treatment stage to remove sand and solid particles from wastewater.

2. Industrial Water Treatment: Applied in treating industrial wastewater to separate solid impurities.

3. Construction Sites: Used to treat sand-containing wastewater generated during construction activities.

4. Mining and Metallurgy: Employed in treating sand-containing wastewater from mining and metallurgical industries.

Maintenance and Care

1. Regular Inspection: Periodically check the wear and tear of the screw conveyor and the interior of the separator, replacing worn parts promptly.

2. Cleaning and Maintenance: Regularly clean accumulated sand and debris inside the separator to keep the equipment clean.

3. Lubrication: Regularly lubricate the bearings and transmission components of the screw conveyor to ensure smooth operation.

The spiral sand-water separator plays a crucial role in sewage treatment and industrial water treatment, effectively improving water quality and reducing the impact of solid impurities on subsequent treatment processes.