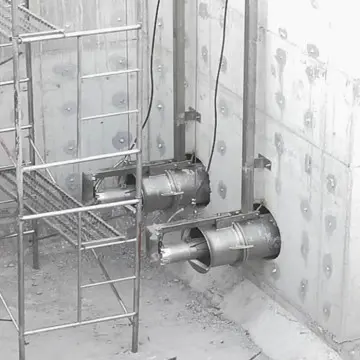

Vertical frame center drive scraper for sewage sedimentation tank

Working Principle

After the raw water is distributed through the central water distribution cylinder, it flows radially towards the overflow weir tank around the pool. The suspended solids in the water body settle at the bottom of the pool, and the supernatant is discharged out of the pool through the overflow weir plate. Through the transmission of the reduction drive and the suspended component, the scraper blade scrapes the sludge into the central sludge collection tank and discharges it out of the pool relying on hydrostatic pressure or a pump.

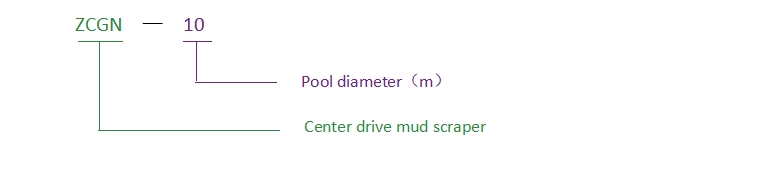

Model Denotation

parameters and selection

|

Model |

Pool diameter(m) |

Pool Depth(m) |

Peripheral line speed(m/min) |

Motor power(kw) |

|

ZCGN-8 |

8 |

2.5~3.5 |

≦3 |

0.55 |

|

ZCGN-10 |

10 |

|

|

0.75 |

|

ZCGN-12 |

12 |

|

|

0.75 |

|

ZCGN-14 |

14 |

|

|

1.1 |

|

ZCGN-16 |

16 |

|

|

1.1 |

|

ZCGN-18 |

18 |

|

|

1.5 |

|

ZCGN-20 |

20 |

|

|

1.5 |

Structural composition

1. Drive Device: It is composed of an asynchronous induction motor, a cycloid pinwheel reducer, gears, a machine base, etc. It has high transmission efficiency, large torque, stable operation, low noise, and is also equipped with a mechanical overload protection function.

2. Main Shaft: It connects components such as the drive device and the scraping arm, transmits power, and drives the scraping arm to rotate.

3. Sludge Scraper Blade: Installed on the scraping arm, it has an oblique intersection design, with good continuity and high sludge collection efficiency. A rubber sludge scraper is often installed under the stainless steel sludge scraper blade to ensure thorough sludge scraping.

4. Overflow Weir Plate: Located around the pool, it is used to control the water level of the supernatant, enabling the supernatant to uniformly enter the effluent channel through the overflow weir plate and be discharged out of the pool.

5. Flow Stabilizing Cylinder: Installed at the center of the pool, it enables the water flow entering the sedimentation tank to be evenly distributed and reduces the interference of the water flow on the sedimentation process.

Features

1. Safe and Reliable Operation: The transmission part adopts dual electrical and mechanical overload protection, which can effectively prevent the equipment from being damaged due to overload.

2. Corrosion Resistance and Long Service Life: The underwater part is made of stainless steel, which has good corrosion resistance and a long service life.

3. High Sludge Scraping Efficiency: The oblique intersection type sludge scraper blade has good continuity and high sludge collection efficiency, and the rubber plate installed under the sludge scraper blade ensures thorough sludge scraping without the phenomenon of floating sludge.

4. Simple Operation and Maintenance: The operation is simple, and remote control can be achieved. Moreover, the equipment structure is relatively simple, making maintenance and management convenient.

Application

It is widely used in sewage treatment projects in industries such as urban areas, chemical engineering, light textiles, and metallurgy. It is an ideal equipment for scraping and removing sludge in radial sedimentation tanks with a diameter generally not exceeding 18m in water plants or sewage treatment plants in water supply and drainage projects.