Vertical frame center drive scraper for sewage sedimentation tank

Working Principle

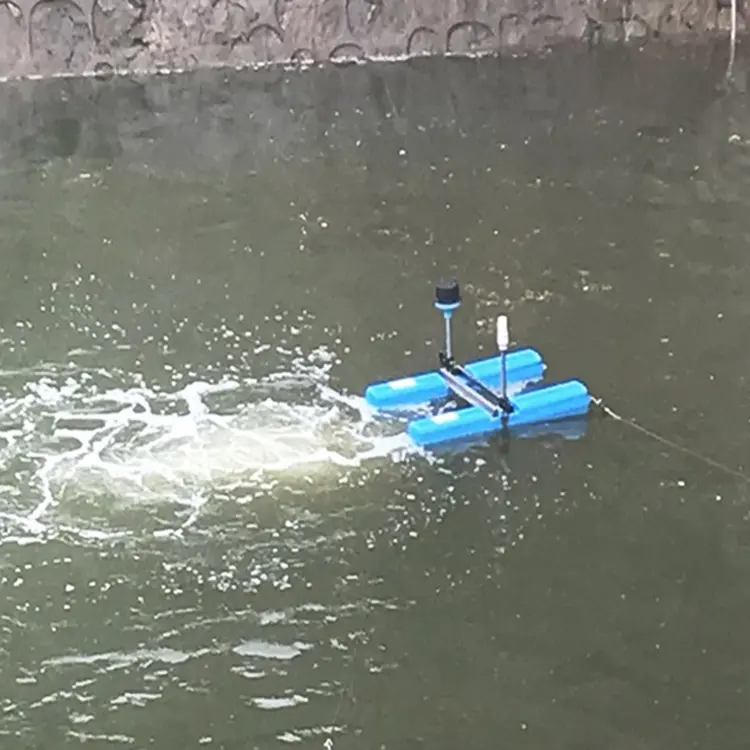

The propeller aerator drives the impeller to rotate through an electric motor. Under the action of the impeller, a powerful thrust is generated, causing the water body to form a directional flow. At the same time, during the rotation of the impeller, air is drawn into the water. Through the gas-liquid mixing device, the air and water are fully mixed to form tiny bubbles, increasing the dissolved oxygen content in the water body and achieving the dual functions of propelling the water flow and aerating.

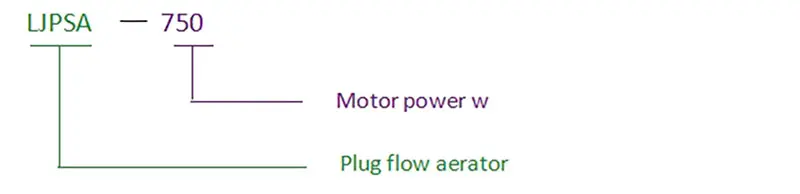

Model Denotation

parameters and selection

|

Model |

Power supply(V) |

Motor power (kw) |

Speed (r/min) |

Weight (kg) |

Oxygenation capacity (kgO2/h) |

Circulating water volume (m³/h) |

Sensing flow(m³/h) |

|

LJPSA-750 |

220/380 |

0.75 |

2850 |

19 |

1.6-1.9 |

280 |

14000 |

|

LJPSA-1200 |

220/380 |

1.2 |

2850 |

20.5 |

1.8-2.1 |

390 |

19000 |

|

LJPSA-1500 |

220/380 |

1.5 |

2850 |

22.5 |

2.3-2.5 |

450 |

23000 |

|

LJPSA-2200 |

380 |

2.2 |

2850 |

26.5 |

3.5-4.5 |

610 |

24500 |

|

LJPSA-3000 |

380 |

3 |

2850 |

30.5 |

4.3-5.3 |

720 |

27000 |

|

LJPSA-4000 |

380 |

4 |

2850 |

36.5 |

5.7-6.8 |

815 |

29500 |

|

LJPSA-5500 |

380 |

5.5 |

2850 |

42 |

7.4-8.3 |

1360 |

32000 |

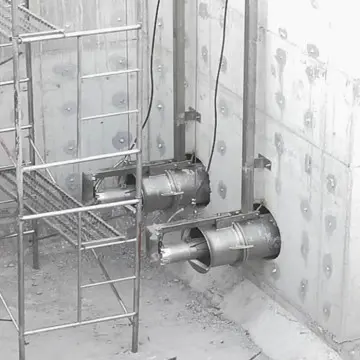

Structural Composition

1.Power System: Usually, high-efficiency and energy-saving motors are used to provide power for the operation of the aerator.

2. Impeller: Generally, it is a specially designed propeller-type impeller that can efficiently push the water flow and draw in air.

3.Flow Guide Cover: Guides the direction of the water flow, making the water flow more stable, improving the propelling efficiency, and protecting the impeller and the motor at the same time.

4.Floating Drum: Made of corrosion-resistant materials, it enables the aerator to float on the water surface and adapt to changes in water levels.

Functional Features

1. Efficient Propulsion: It can generate a strong water flow thrust, causing the water body to form a large-scale directional flow, effectively preventing the eutrophication of the water body and the excessive reproduction of algae, and promoting the self-purification ability of the water body.

2.Good Oxygenation Effect: The air is fully mixed into the water to form tiny bubbles, increasing the gas-liquid contact area and improving the oxygen transfer efficiency, providing sufficient oxygen for aquatic organisms.

3. Low Energy Consumption: With an advanced design and energy-saving motor, while achieving efficient propelling and aerating, it reduces energy consumption and has a relatively low operation cost.

4. Convenient Installation and Maintenance: The overall structure is compact, with a small volume. It is simple to install and can be flexibly arranged in the water body according to needs, and the maintenance workload is small.

6.Corrosion Resistance: Key components are made of stainless steel or corrosion-resistant materials, suitable for wastewater environments.

Application Fields

1. Urban Landscape Water Bodies: Such as park lakes and urban artificial rivers, etc., which can improve water quality and create beautiful water scenery.

2. Industrial Wastewater Treatment: In industrial wastewater treatment tanks, it promotes the circulation and aeration of the wastewater, improving the wastewater treatment effect.

3.Aquaculture: It provides sufficient oxygen and water flow for aquaculture ponds, improves the aquaculture environment, and increases the aquaculture density and output.

4.River Treatment: It is used for the ecological restoration and water quality improvement of water bodies such as urban rivers and rural rivers, enhancing the fluidity and self-purification ability of the water body.